What Are Structural UV-Curing Adhesives, and How Do They Work?

What Are Structural UV-Curing Adhesives, and How Do They Work?

Structural UV-curing adhesives have gone through the roof recently for their remarkable attributes and many uses. These adhesives boast a speedy curing timeframe, sky-high bond durability, and invulnerability to environmental conditions – enough said! So, let’s dive deeper into what structural UV-curing adhesives are all about…and how they work that magic!

Understanding UV-Curing Adhesives

The mysterious ultraviolet, or UV for short, is a type of electromagnetic radiation beyond what we can see with the human eye. Somehow more powerful than visible light, it’s found naturally in sunlight but also gets tapped to provide us with artificial sources like tanning beds and bright neon black lights! Although this invisible force brings both good and bad. On the one hand, it helps give our bodies much-needed vitamin D production; yet on the other hand, too much exposure causes serious issues: sunburns caustic enough to warp skin cells like an oven door left open just one second too long and an ever-alarming cancer risk.

UV radiation given off by the sun not only affects our skin and eyes if exposed too long, but it also impacts the environment. Plants and aquatic life are in jeopardy when unprotected from its rays. To prevent any harm to oneself and the planet, waterproof clothing, sunscreen, and staying out of direct sunlight during peak hours of light should be taken seriously.

It’s not all bad, though; UV radiation is also powerful for other reasons, like producing vitamin D naturally within our body. It’s even used commercially for sanitation purposes or creating fluorescent lights and safe product coatings. So, although you must be careful of overexposure to this good-and-bad energy force, you should remember that it can do some great things with proper handling!

The Role of Photoinitiators

Photoinitiators are small but mighty chemical compounds that grandly ignite the process of photopolymerization. This is when a liquid monomer morphs into solid polymer form with the help of light – making possible all kinds of adhesive, coating, and dental applications.

They’re typically brought in just before exposure to light. They get down to business absorbing energy and going through their inner transformation – generating free radicals that create an unstoppable chain reaction for polymer formation. Amazingly, photoinitiators have revolutionized many aspects of the world around us by swiftly and quite brilliantly advancing several manufacturing processes.

Why Structural UV-Curing Adhesives are so popular?

Fast Curing Times

Structural UV-curing adhesives are a cut above traditional adhesives – not just because they cure incredibly fast but also due to their impact on the industry. Instead of waiting hours or days for systems and parts to be secured with traditional glues, we can now harness UV light’s power and see results in seconds or minutes! This is an especially strong bond for car manufacturers with only a while to bond components. That way, they can zoom ahead on production times without sacrificing quality control.

Undoubtedly, the electronics industry has experienced a surge in efficiency, with UV-curing adhesives joining the fray. Incredibly quick curing times have slashed assembly wait times and gear up production rates with ease – making them very convenient to those wanting to get stuff done ASAP!

High Bond Strength

Structural UV-curing adhesives are like the ultimate bonders – offering outstanding strength and resilience no matter what conditions they’re up against. These incredibly reliable adhesives, through rapid polymerization, form strong molecular connections to substrates that won’t come undone under heavy loads, vibrations, or even rapid temperature changes. That’s why manufacturers with high-end expectations trust their applications to structural UV-curing adhesives; they’ve certainly got the grit to live up to them!

Structural UV-curing adhesives are a game-changer when it comes to creating bonds. They have revolutionized how things like the automotive, aerospace, and construction industries work, allowing for an ultra-fast bond so that production is skyrocketing with minimal costs – something these businesses need more than ever. Reliability and satisfaction come hand in hand with this option; you can guarantee your materials’ incredibly strong and durable joining. It’s no wonder they’ve become such popular players on the bonding stage!

Versatile Applications

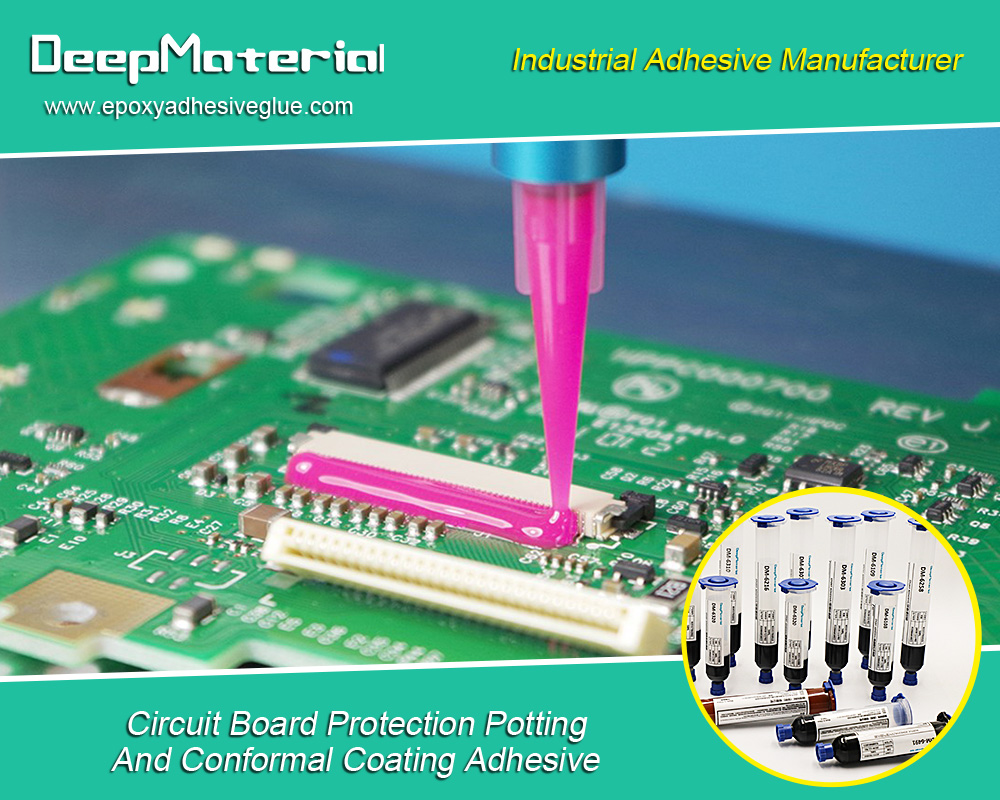

UV-curing adhesives provide a versatile choice when it comes to bonding different materials. From glass and metal to plastic and composites, these strong bonds are essential for various industries – electronics, automotive, medical devices, and even aerospace! In the fast-paced world of electronics, UV-curing adhesives offer an ideal solution with their ability to stick together circuit boards and microchips swiftly – yet durably enough that whatever temperature or conditions an electronic device might face won’t be any match!

In the auto racing world, UV-cured adhesives are indispensable for sticking windshields and body panels together. They make it possible to have lightweight vehicles that get you farther with less fuel – a real win-win. For medical supplies, these UV glues let different materials like plastics and metals bond together tightly to create all kinds of medical accessories, such as catheters and surgical tools. There is no doubt about it – this adhesion technique is truly invaluable!

Environmental Resistance

UV-curing adhesives are sticky and boast impressive resilience to climate conditions – heat, humidity, and even chemicals. When exposed to ultraviolet rays, these babies harden fast and create quite a strong bond. What’s more, after curing, they form a kind of protection against things like grinding weather or contact with hazardous materials. In short, when you need solid results that stand up over time – look no further than this glue!

This resilient resistance guarantees the seal stays strong and trusty, even under tough conditions – making it ideal for projects where dependability and durability are essential. You can trust its lasting power, whether used in commercial operations or simply at-home mends. UV-curing adhesives offer an indestructible means of joining materials.

Controlled Curing Process

UV-curing adhesives give producers the superpower of flexibility in their curing process – they can play with curing time by tweaking intensities and photoinitiators until exactly what they need to make a smooth, efficient manufacturing experience is achieved. This level of immense control lets them regulate their products’ strength and durability while maintaining precision to exacting standards set by industries such as electronics, automotive, and medical devices. This maximizes safety concerns and puts them on track for faster production workflows with no fear of over- or under-curing!

Final Words

In sum, structural UV-curing adhesives bring many advantages to the game – they’re strong and durable, abide by lightning-fast curing times, and provide easy use. How can one sealant do all this? It’s as if the sun has finally shone upon our industrial needs. Suddenly, the bond hardens in seconds, leading to jam-packed production line speeds! A dream come true for anyone looking for productive methods…

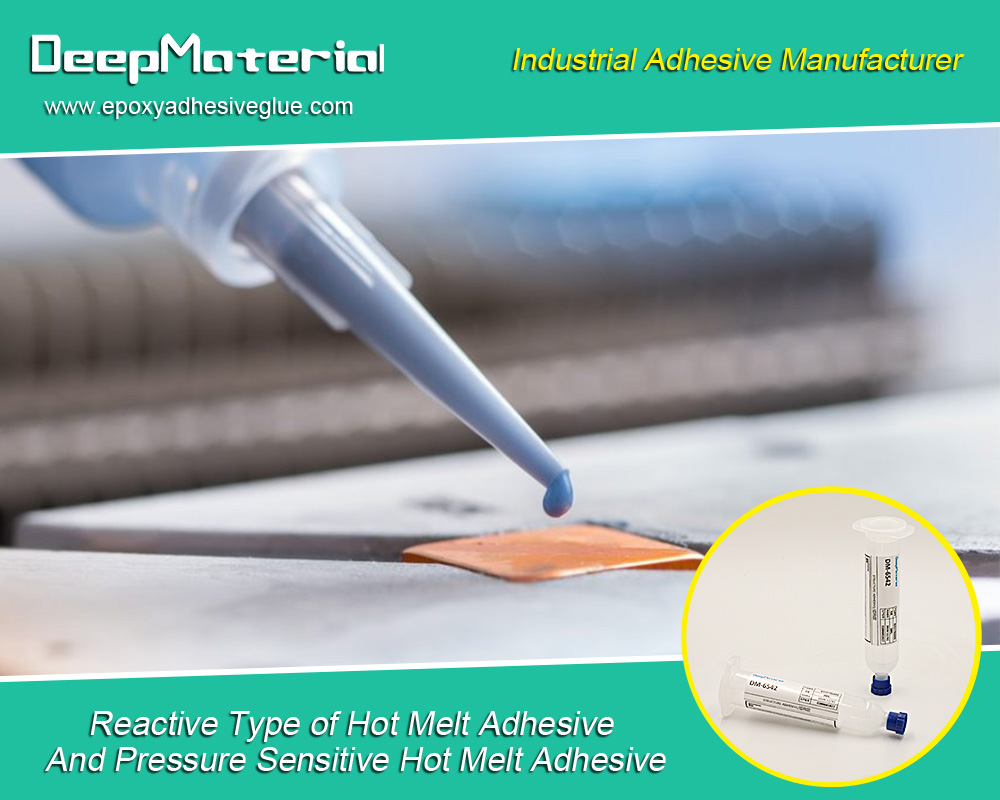

For more about choosing the best Structural UV-Curing Adhesives, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.