Best epoxy adhesive glue manufacturer and supplier

Epoxy adhesives glue are versatile and offer a robust bonding solution for various applications. Understanding epoxy adhesives’ composition, types, and applications can help you choose the suitable adhesive for your project and achieve a successful bond.You can ensure a long-lasting and durable bond with epoxy adhesives by following proper preparation and application techniques.

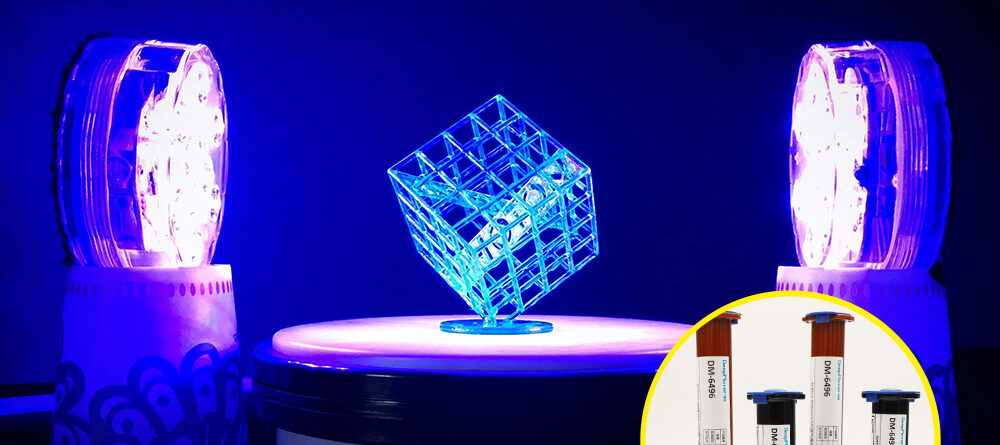

Epoxy adhesives glue provide excellent adherence to a wide range of surfaces and are the most commonly used structural adhesives. Epoxy adhesives can be cured at room temperature, at increased temperatures, or via UV light radiation, depending on the type of curing agent used. Numerous epoxy adhesives, either one-component or two-component, have been marketed and widely utilized in various industrial production and applications for bonding metals, concrete, glass, ceramics, concrete, many plastics, wood, and other materials.

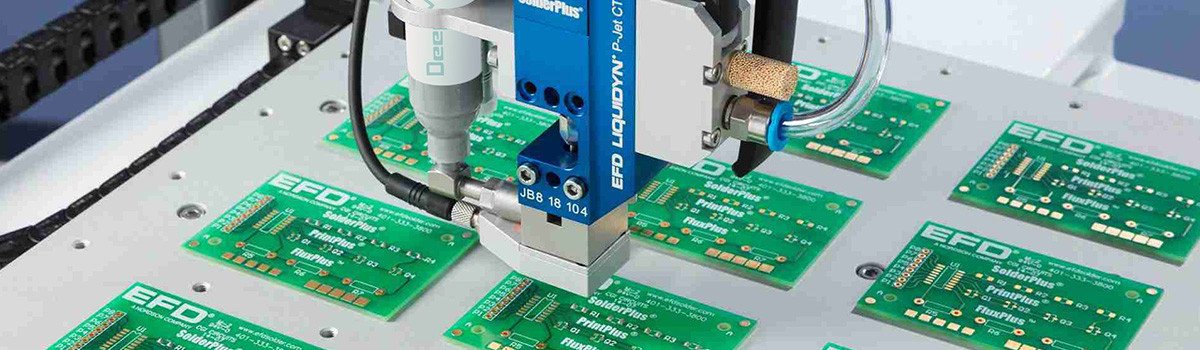

Shenzhen DeepMaterial Technologies Co., Ltd is a professional epoxy adhesive glue manufacturer and supplier in china. DeepMaterial mainly offering one component epoxy adhesive,two component epoxy adhesive,epoxy encapsulant,UV Curing optical adhesives,epoxy conformal coating,smt epoxy adhesives,epoxy potting compound,waterproof epoxy and so on.

DeepMaterial waterproof epoxy adhesive is for plastic,metal,glass,concrete,aluminium,composites and so on.

Complete Guide Of Epoxy Adhesive Glue:

What is an epoxy adhesive?

Epoxy adhesive glue is a thermosetting adhesive made up of a resin or epoxy polymer and a hardener that is used to adhere or join a range of surfaces together with a strong, permanent, and robust bond that can tolerate extreme stress and weather conditions.

Epoxy adhesives glue are the most widely used industrial adhesives, as well as the most adaptable structural adhesives. The tenacity of the cured product, as well as their incredible ability to stick to a wide range of materials, contribute to the popularity of epoxy adhesive. Epoxy resin glue solutions are very simple to customize to satisfy the specific property requirements of each project.

Epoxy adhesives are made with several epoxy adhesive resin types, which define the glue’s fundamental features. When high temperature resistance is necessary, a heat resistant epoxy resin is the ideal choice, whereas a flexible epoxy resin is the best choice when movement is possible.

Epoxy adhesives are commonly offered as either one component or two component systems. One component epoxy adhesives are generally cured at temperatures between 250-300°F, conditions that engineer a product of high strength, excellent adhesion to metals, and outstanding environmental and harsh chemical resistance. In fact, this product is often used as an alternative to welding and rivets.

An epoxy adhesive is a type of two-part adhesive that consists of a resin and a hardener. A chemical reaction occurs when the two components are mixed, forming a solid and durable bond. Epoxy adhesives are known for their high strength, excellent durability, and resistance to chemicals and heat.

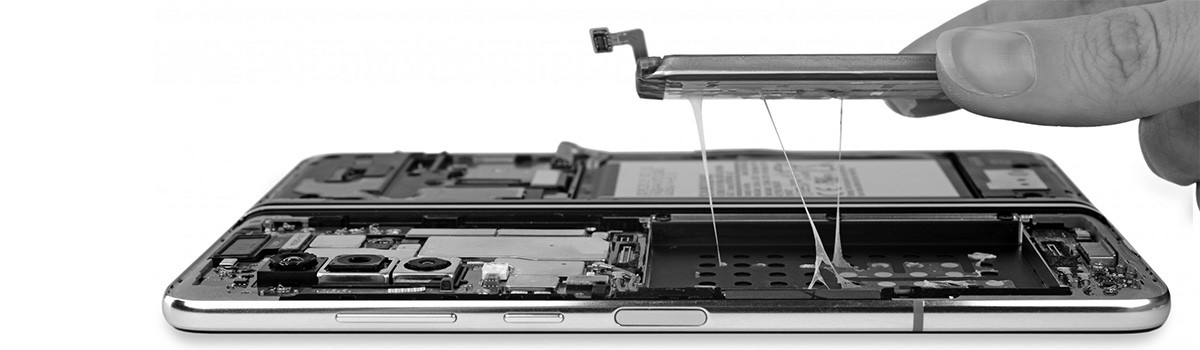

They also have good gap-filling properties and can bond with various materials, including metals, plastics, ceramics, and composites. One of the critical benefits of epoxy adhesives is their ability to create a strong bond, even on smooth or non-porous surfaces. Epoxy adhesives are available in various forms, including paste, liquid, film, and preformed shapes.

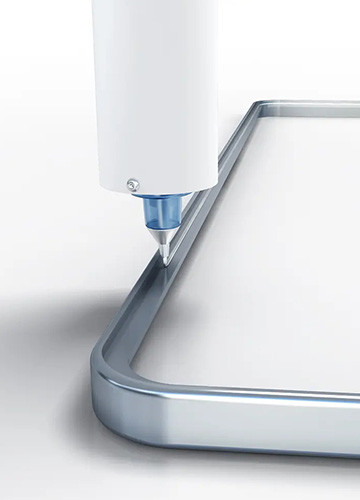

They can be applied using various techniques, including brush, roller, spray, and syringe. The curing time for epoxy adhesives can vary depending on the type of resin and hardener used, as well as the temperature and humidity of the environment.

Epoxy adhesives are available in a range of different formulations, each with its own specific properties. Some formulations are designed for high strength and durability, while others are designed for flexibility and impact resistance. Selecting the correct epoxy adhesive for the application ensures the best possible performance.

Epoxy adhesives are their ability to bond to a wide range of surfaces. They also resist chemicals, heat, and water, making them ideal for harsh environments. Additionally, epoxy adhesives have excellent mechanical properties, such as high tensile strength and stiffness, making them suitable for load-bearing applications.

Epoxy adhesives are reliable adhesives that offer strong, durable bonds in various applications. They resist harsh environmental conditions and can fill gaps and voids between surfaces. They are widely used in many industries and applications and can be customized to meet specific requirements. However, their use requires proper handling and safety precautions to ensure optimal performance and safety.

Types of epoxy adhesive glue

There are different types of epoxy adhesive glue available in the market, including:

Standard Epoxy: This type of epoxy adhesive glue is a general-purpose adhesive suitable for bonding a wide range of materials such as wood, metal, plastic, and ceramics. It is ideal for repairing household items and for DIY projects.

Fast-setting Epoxy: This epoxy adhesive glue is designed to cure quickly, typically within a few minutes, making it ideal for time-sensitive projects. It is commonly used in automotive and industrial applications.

Structural Epoxy: Structural epoxy adhesive glue is a high-strength adhesive suitable for bonding load-bearing components such as metals, composites, and plastics. It is commonly used in the construction and aerospace industries.

Optically Clear Epoxy: This type of epoxy adhesive glue is transparent and does not yellow over time, making it ideal for applications where clarity is essential, such as glass bonding and jewelry making.

High-temperature Epoxy: This type of epoxy adhesive glue is formulated to withstand high temperatures, making it suitable for bonding materials exposed to heat, such as engines, exhaust systems, and industrial equipment.

Water-resistant Epoxy: This type of epoxy adhesive glue is designed to resist water and moisture, making it ideal for the marine and outdoor applications where exposure to water is a concern.

UV-resistant Epoxy: UV-resistant epoxy adhesive glue is formulated to resist fading and yellowing when exposed to sunlight, making it suitable for outdoor applications such as bonding plastic and fiberglass.

Flexible Epoxy: Flexible epoxy adhesive glue is designed to bond materials that undergo movement and vibration, such as plastics, rubber, and metal. It is commonly used in automotive and marine applications.

Metal-filled Epoxy: Metal-filled epoxy adhesive glue contains metal particles, which makes it ideal for repairing metal surfaces and components. It is commonly used in automotive and industrial applications.

Color-matched Epoxy: Color-matched epoxy adhesive glue is available in various colors, making it ideal for applications where color matching is essential, such as repairing automotive finishes and filling gaps in the wood.

Electrical Epoxy: Electrical epoxy adhesive glue is formulated to be non-conductive, making it ideal for bonding and sealing electrical components and circuit boards.

What is epoxy adhesive glue made Of?

The adhesive is made of two components, the resin and the hardener, which, when mixed together, react to form a durable and long-lasting bond.

The resin component of epoxy adhesive is typically made of a mixture of bisphenol-A (BPA) and epichlorohydrin (ECH), two chemicals that are reacted together to form a polymer. BPA is a type of organic compound commonly used in the production of plastics, while ECH is a reactive chemical used as a crosslinking agent in the formation of polymers. The resulting polymer is a viscous, liquid substance with a high degree of chemical and thermal stability, making it an ideal material for adhesive use.

The hardener component of epoxy adhesive is typically made of amines or polyamides, which are chemicals that react with the resin to form a crosslinked network of molecules. The hardener component is usually mixed with the resin component in a 1:1 ratio, and the resulting mixture is then applied to the surfaces to be bonded.

When the epoxy adhesive is applied to the surfaces, the resin and hardener form a robust and durable bond resistant to water, chemicals, and heat. The bond can also withstand mechanical stress and vibration, making epoxy adhesive an ideal choice for applications requiring a robust and long-lasting bond.

When evaluating the efficacy of an epoxy adhesive, it’s helpful to look at the general composition of the compounds that make it up. Polymerization of a mixture of two initial components, the resin and the hardener, produces epoxies. Epoxy adhesives consist primarily of epoxy resin and a curing agent. Filler, toughener, plasticizer, and additional additives including silane coupling agent, deformer, and colorant, among others, can be added as needed.

| Constituent | Ingredient | Main Role |

|---|---|---|

| Primary | Epoxy resin, reactive diluent | Adhesive base |

| Primary | Curing agent or catalyst, accelerator | Curability |

| Modifying | Filler | Property Modification |

| Modifying | Toughener | Toughening |

| Modifying | Plasticizer | Flexibility |

| Additive | Coupling Agent | Adhesion |

| Additive | Colorant | Color |

Epoxy resins are primarily made by reacting active hydrogen from phenols, alcohols, amines, and acids with epichlorohydrin, commonly abbreviated as ECH, under carefully regulated conditions. Epoxy resin can also be made by oxidizing an olefin with peroxide, similar to how cycloaliphatic epoxy resins are made.

Bisphenol A diglycidyl ether, sometimes known as bisphenol A type epoxy resin, was the first commercially available epoxy resin and is still the most extensively used today. This form of epoxy resin is expected to account for roughly 75% of epoxy resin used in industry on a volume basis.

Bisphenol A diglycidyl ether, the most common epoxy resin used in epoxy adhesives, has a chemical structure and important properties of numerous functional groups.

How to make an epoxy adhesive glue

Here’s a simple guide on how to make an epoxy adhesive:

Materials:

- Epoxy resin

- Hardener

- Mixing cup

- Stir stick

- Protective gloves

- Safety glasses

Instructions:

- First, select the appropriate epoxy resin and hardener for your application. Make sure to follow the manufacturer’s instructions for the correct mixing ratios.

- Put on your protective gloves and safety glasses to protect your skin and eyes from the epoxy.

- Measure the proper amount of epoxy resin and hardener into a mixing cup. The exact amounts will depend on the specific product you’re using, so follow the manufacturer’s instructions carefully.

- Use a stir stick to thoroughly mix the epoxy resin and hardener together. Be sure to scrape the sides and bottom of the mixing cup to ensure that the mixture is thoroughly combined.

- Continue stirring the mixture until it becomes uniform with no streaks or lumps.

- Apply the epoxy adhesive to the surfaces you wish to bond together. Follow the manufacturer’s instructions for the correct application method and wait time before bonding the surfaces.

- Allow the epoxy adhesive to cure completely before handling or applying any load to the bonded surfaces. The curing time will depend on the specific product you’re using and the temperature and humidity of your environment.

How does epoxy adhesive glue work?

Epoxy adhesives are two-part adhesives that consist of a resin and a hardener. When these two components are mixed, a chemical reaction occurs, causing the mixture to harden and form a strong, durable bond.

The resin and hardener components of the epoxy adhesive each have reactive groups that can react with each other to form covalent bonds. These robust bonds can withstand stress, making epoxy adhesives ideal for high-stress applications.

The chemical reaction between the resin and hardener components of the epoxy adhesive is called a curing reaction. During the curing process, the epoxy adhesive typically goes through two stages: the initial and final.

During the initial curing process, the epoxy adhesive will remain somewhat fluid and can be easily spread and manipulated. As the curing reaction progresses, the mixture will become thicker and harder to work with.

During the final stage of the curing process, the epoxy adhesive will become fully cured and hard. Once cured, the epoxy adhesive will form a strong bond with the materials it has been applied, creating a solid and durable bond that can withstand stress and strain.

Epoxy adhesive is the ability to bond to a wide variety of materials, and this includes metals, plastics, ceramics, wood, and other materials. The adhesive is also resistant to water, heat, and chemicals, making it ideal for harsh environments.

To use epoxy adhesive, the two components must be mixed together in the correct proportions. Once the adhesive has been integrated, it must be applied to the surfaces that are to be bonded. Depending on the specific formulation, the adhesive will typically work for several minutes to several hours.

As the epoxy adhesive cures, it will harden and form a strong, permanent bond. The curing time will depend on various factors, including the adhesive layer’s temperature, humidity, and thickness.

How to use epoxy adhesive glue on plastic

Using epoxy glue on plastic is a simple process that requires a few basic steps. Here is a step-by-step guide on how to use epoxy glue on plastic:

- Clean the surface: Before applying the epoxy glue, make sure the plastic cover is clean and free of any dirt, dust, or grease. You can use a cleaning agent or rubbing alcohol to wipe down the surface and let it dry completely.

- Mix the epoxy: Epoxy glue usually comes in two parts – the resin and the hardener. Mix equal amounts of both parts thoroughly in a disposable container until completely blended.

- Apply the epoxy: Using a small brush or toothpick, apply the mixed epoxy to the plastic surface in a thin, even layer. Make sure you cover the entire area that needs to be bonded.

- Press the pieces together: After applying the epoxy, carefully press them together and hold them in place for a few minutes to allow the glue to set. You can also use a clamp or tape to hold the pieces in place while the epoxy cures.

- Allow to cure: Leave the epoxy to fix for the recommended time, usually 24 to 48 hours. To ensure a strong bond, avoid moving or disturbing the glued pieces during this time.

Tips for using epoxy glue on plastic:

- Choose the correct type of epoxy glue for the job. Some epoxy glues are specifically designed for plastic and will provide a stronger bond than others.

- Avoid using too much epoxy, as this can weaken the bond and cause it to break down over time.

- Work in a well-ventilated area and wear gloves to protect your skin from the chemicals in the epoxy.

- Use a disposable container and mixing tool to avoid contaminating the epoxy.

- Follow the manufacturer’s instructions carefully, as curing times may vary depending on the brand and type of epoxy glue.

- Test the bond strength before using the repaired item to ensure it is secure.

How to use epoxy adhesive glue on metal

Epoxy adhesive glue is a strong adhesive that can bond metal surfaces together. Here are the steps to use epoxy glue on metal:

1.Clean the metal surfaces: Before applying epoxy glue, clean the metal surfaces thoroughly with a degreaser or alcohol to remove any dirt, oil, or grease.

2.Roughen the surface: Use sandpaper or a file to roughen the surface of the metal. This will help the epoxy to adhere better to the metal.

3.Mix the epoxy: Mix the epoxy according to the instructions on the package. Make sure to mix the two components thoroughly.

4.Apply the epoxy: Apply the epoxy to one of the metal surfaces using a brush or a spatula. Make sure to apply an even layer of epoxy.

5.Press the surfaces together: Press the two metal surfaces together firmly. You can use clamps to hold the metal surfaces while the epoxy dries.

6.Let the epoxy dry: Let the epoxy dry according to the instructions on the package. It usually takes around 24 hours for the epoxy to fully cure.

7.Sand and paint: Once the epoxy has fully healed, you can sand any rough edges and paint the metal surfaces if desired.

8.Use in a well-ventilated area: Epoxy glue can emit fumes that can be harmful if inhaled. Make sure to work in a well-ventilated area or wear a mask to protect your lungs.

9.Avoid skin contact: Epoxy glue can be challenging to remove from the skin, so wear gloves to avoid direct contact with the adhesive.

10.Follow the instructions carefully: Read and follow the instructions on the package carefully. Mixing ratios and drying times can vary depending on the brand of epoxy glue you are using.

11.Test the bond strength: Before using the bonded metal for any load-bearing purposes, test the bond strength by applying pressure to the joint.

How long does epoxy adhesive glue last?

The lifespan of epoxy adhesive glue can vary depending on several factors, such as the specific type of epoxy used, the conditions it is exposed to, and the way it is stored. In general, however, epoxy adhesive glue can last for several years when properly stored and used.

Most epoxy adhesive glues have a shelf life of around 1-2 years when stored in a cool, dry place and tightly sealed. Some manufacturers may specify a longer or shorter shelf life for their products, so checking the label or product information for specific guidelines is essential.

Once the epoxy adhesive glue is applied and cured, it can last very long if it is not exposed to extreme temperatures or harsh chemicals. Epoxy adhesive glues are known for their strong bonding properties and can withstand significant stress, making them ideal for use in many different applications.

To ensure the longest possible lifespan for epoxy adhesive glue, it is crucial to follow proper storage and usage guidelines. This includes storing the glue in a dry and cool place away from direct sunlight or heat sources, as exposure to high temperatures can cause the glue to degrade more quickly. Additionally, storing the glue in an airtight container can help prevent moisture from entering and damaging the adhesive.

When using epoxy adhesive glue, carefully following the manufacturer’s instructions, including the recommended mixing ratio and curing time, is essential. Failure to do so can result in a weaker bond or even complete loss of the adhesive. When handling epoxy adhesive glue, the appropriate safety gear, such as gloves and protective eyewear, must also be used.

Sometimes, epoxy adhesive glue may begin to yellowish or discolor over time. While this does not necessarily indicate a loss of strength, it can affect the appearance of the bonded surfaces. Some types of epoxy adhesive glue may also develop a slightly sticky or tacky texture after prolonged exposure to air, which can attract dust and other debris.

However, exposure to UV light or moisture can cause epoxy adhesive glue to break down over time, which may weaken its bonding strength. It is also important to note that some types of epoxy adhesive glue may become brittle over time, affecting its performance.

However, exposure to UV light or moisture can cause epoxy adhesive glue to break down over time, which may weaken its bonding strength. It is also important to note that some types of epoxy adhesive glue may become brittle over time, affecting its performance.

How long for epoxy adhesive glue take to dry

The drying time of epoxy adhesive can vary depending on several factors, such as the type used, temperature, humidity, and the surfaces being bonded.

Most epoxy adhesives will generally dry to the touch within 30 minutes to an hour. However, the bond can take up to 24 hours or longer to fully cure and reach its maximum strength.

Some quick-setting epoxy adhesives are designed to cure faster and may reach maximum strength in as little as 5-10 minutes. However, following the manufacturer’s instructions for the specific adhesive being used is essential to ensure the best results.

In addition, it’s important to note that temperature and humidity can affect the drying time of epoxy adhesives. Higher temperatures and lower humidity levels can speed up the curing process, while lower temperatures and higher humidity levels can slow it down.

When using epoxy adhesive, it’s essential to follow safety precautions, such as wearing gloves and working in a well-ventilated area. It’s also necessary to properly store and handle the adhesive to prevent it from drying out or becoming unusable.

If you need clarification on the drying time or application of a specific epoxy adhesive, it’s best to consult the manufacturer’s instructions or contact their customer service for guidance.

While the drying time of epoxy adhesive can vary, it’s essential to be patient and allow enough time for the bond to fully cure before putting any stress or weight on it. Rushing the drying process can result in a weak or failed bond, so it’s best to err on caution and wait for the recommended curing time.

How to find the best epoxy adhesive glue

Finding the best epoxy adhesive glue can be daunting, as numerous options are available in the market. Here are some factors to consider when choosing an epoxy adhesive glue:

Bond strength: Look for an epoxy adhesive glue with high bond strength. This will ensure it can hold your materials together for a long time.

Drying time: The drying time of the epoxy adhesive glue is an essential factor to consider. Some epoxies may take longer to dry, which can be inconvenient if you need to finish your project quickly.

Versatility: Check if the epoxy adhesive glue is versatile enough for various materials. You should look for an epoxy that can bond with different surfaces such as metal, wood, ceramics, plastics, and glass.

Temperature resistance: If you plan to use epoxy adhesive glue in extreme temperatures, you must find an epoxy that can withstand these conditions.

Clarity: If you are using epoxy adhesive glue for a project where aesthetics matter, you should choose an epoxy that dries clear, so it won’t affect the appearance of your project.

Safety: Ensure the epoxy adhesive glue is safe and doesn’t contain harmful chemicals. Check if it has any toxic fumes and if you need to use any protective gear while applying it.

Brand reputation: Look for reputable brands with positive reviews from previous customers. You can check online reviews or ask for recommendations from people who have used epoxy adhesive glue.

Application method: Consider the ease of use and application method of the epoxy adhesive glue. Some epoxies come in a two-part formula that requires mixing, while others come in a pre-mixed form. Choose the one that suits your needs and comfort level with the application.

Curing time refers to the time it takes for the epoxy adhesive glue to reach its maximum strength. Different epoxies have varying curing times, so consider how quickly you need your project ready.

Storage and shelf life: Check the epoxy adhesive glue’s storage requirements and shelf life. Some epoxies may require special storage conditions or have a limited shelf life, affecting their effectiveness over time.

Price: Consider your budget when choosing an epoxy adhesive glue. Epoxies come in different price ranges, so choose one that fits your budget while meeting your requirements for bond strength, versatility, and other factors.

Testing and experimentation: It’s always a good idea to test the epoxy adhesive glue on a small sample before using it on your project. This will help you ensure it meets your expectations regarding bond strength, drying time, and other factors.

The lifespan of epoxy adhesive glue

The lifespan of epoxy adhesive glue can vary depending on several factors, including the specific formulation of the epoxy, the conditions under which it is used and stored, and the materials it is used to bond.

In general, epoxy adhesive glue has a shelf life of around one year if stored in a cool, dry place and tightly sealed. Once the epoxy is mixed and applied, the curing process begins, and the epoxy will harden and become fully cured within 24 to 48 hours.

Once fully cured, epoxy can provide a robust and durable bond lasting many years. However, the bond’s lifespan will depend on several factors, such as the amount of stress and strain placed on the bond, exposure to environmental factors such as temperature and moisture, and the quality of the bonded surfaces.

If the bonded surfaces are clean, dry, and properly prepared, the bond created by epoxy adhesive glue can last for many years, even in harsh environments. However, if the surfaces are dirty, greasy, or improperly prepared, the bond may fail prematurely.

It is also essential to note that the lifespan of the bond created by epoxy adhesive glue can be affected by exposure to UV light. UV light can cause the epoxy to break down over time, leading to a weakening of the bond. Therefore, it is recommended to use UV-resistant epoxy when bonding materials that will be exposed to sunlight.

Additionally, if the epoxy is used in a high-stress application or exposed to constant vibration, the bond’s lifespan may be shorter. In such cases, it may be necessary to reinforce the bond with mechanical fasteners or other bonding agents.

The lifespan of epoxy adhesive glue depends on several factors, and it is essential to follow the manufacturer’s recommendations for storage, preparation, and application to ensure the best possible bond. If used correctly, epoxy adhesive glue can provide a long-lasting and robust bond suitable for a wide range of applications.

How to properly store epoxy adhesives glue

Proper storage of epoxy adhesives is crucial to ensure their effectiveness and longevity. Here are some guidelines on how to properly store epoxy adhesives:

1.Store in a cool, dry place: Epoxy adhesives should be stored in a cool, dry place away from direct sunlight, heat sources, and moisture. Excessive heat or humidity can cause the adhesive to degrade, thicken, or cure prematurely.

2.Keep containers tightly sealed: Epoxy adhesives should be stored in original containers to prevent air or moisture from entering. Exposure to air can cause the adhesive to harden or cure, reducing its effectiveness.

3.Use within the recommended shelf life: Epoxy adhesives have a limited shelf life, usually six months to two years. Check the expiration date on the label and use the adhesive within the recommended time frame to ensure its effectiveness.

4.Store away from incompatible materials: Epoxy adhesives should be stored away from incompatible materials such as acids, bases, oxidizers, and flammable liquids. These materials can react with the adhesive, causing it to degrade or become unsafe.

5.Label containers clearly: Clearly label containers with the name of the adhesive, the date of purchase, and the expiration date to prevent confusion and ensure proper use.

6.Store in a stable position: Epoxy adhesives should be stored in a stable, upright position to prevent leaking or spills. If the adhesive is accidentally spilled, it can be challenging to clean up and can pose a safety hazard. Avoid freezing: Some types of epoxy adhesives can be damaged by freezing. Check the label to see if the adhesive should be stored above freezing temperatures.

7.Rotate stock: To ensure freshness and effectiveness, rotating stock and using older adhesives before opening newer containers is a good practice. Handle with care: Epoxy adhesives should be handled carefully to prevent damage to the container or accidental spills. When handling the adhesive, use appropriate protective equipment, such as gloves and eye protection.

8.Dispose of properly: When disposing of epoxy adhesives, follow the manufacturer’s recommendations or local regulations for proper disposal. Do not pour the adhesive down the drain or throw it in the trash. Proper storage of epoxy adhesives is essential to maintain their effectiveness and ensure safe use. By following these guidelines, you can extend the shelf life of your adhesive and prevent accidents or damage to the environment.

How to remove cured epoxy adhesive glue

Removing cured epoxy adhesive can be challenging, but there are a few methods you can try:

1.Heat: Applying heat to the epoxy can soften it and make it easier to remove. Use a heat gun or a hairdryer to apply heat to the epoxy. Be careful not to overheat the surrounding area, and wear protective gloves and goggles.

2.Solvents like acetone, alcohol, or vinegar can dissolve the epoxy adhesive. Soak a cloth or a paper towel in the solvent and apply it to the epoxy. Leave it for a few minutes to allow the solvent to work, and then scrape off the epoxy with a plastic scraper.

3.Mechanical methods: You can use a knife, chisel, or sandpaper to scrape off the cured epoxy. Be careful not to damage the surface underneath the epoxy.

4.Epoxy remover: Commercial epoxy removers can help dissolve and remove the cured epoxy adhesive. Follow the instructions on the product carefully, and wear protective gloves and goggles.

5.Ultrasonic cleaning: Ultrasonic cleaning is a technique that uses high-frequency sound waves to remove cured epoxy from surfaces. This method is beneficial for small items with intricate shapes or hard-to-reach areas.

6.Abrasive materials: Using abrasive materials like a wire brush, sandpaper, or a rotary tool with a sanding attachment can help remove the epoxy. However, be careful not to scratch or damage the surface underneath the epoxy.

7.Regardless of your chosen method, wearing protective gloves and goggles to protect your skin and eyes is essential. You should also work in a well-ventilated area to avoid inhaling fumes or particles.

It is important to note that removing cured epoxy adhesive can be a time-consuming and challenging process. Prevention is the best course of action, so following the instructions carefully when using epoxy is essential, and avoiding getting it on surfaces you don’t want it to stick to.

Epoxy adhesives glue: types, applications, benefits, and classes

Here is a breakdown of epoxy adhesives’ different types, applications, benefits, and classes.

Types of Epoxy Adhesives:

1.One-part epoxy: These are pre-mixed adhesives that cure at room temperature. They are used for small bonding jobs and repairs.

2.Two-part epoxy: These are two-component adhesives that require mixing before use. They cure at room temperature or at elevated temperatures.

3.Structural epoxy: These are high-strength adhesives used for bonding metals, composites, plastics, and other materials in structural applications.

4.Clear epoxy: These are transparent adhesives for bonding glass, plastics, and other materials where an evident bond is desired.

5.Flexible epoxy: These are adhesives that have a degree of flexibility and are used for bonding materials that undergo thermal expansion or contraction.

Applications of Epoxy Adhesives:

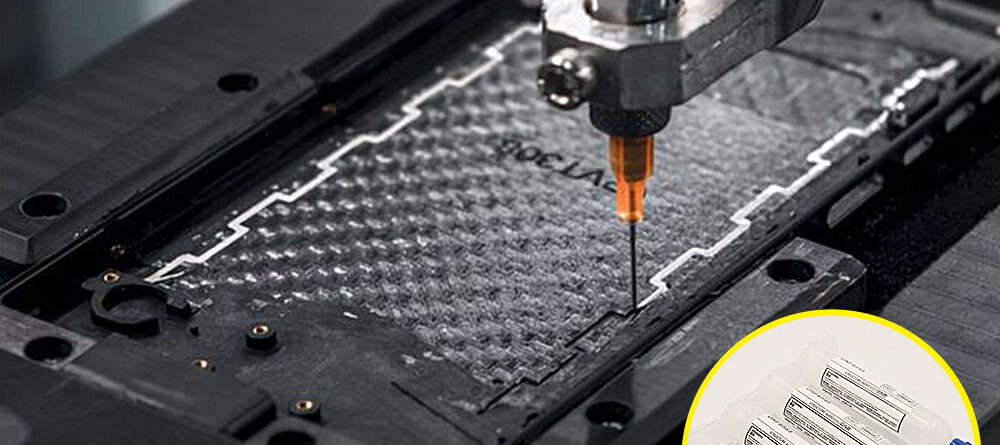

1.Automotive: Epoxy adhesives are used for bonding body panels, windshields, and other parts in the automotive industry.

2.Construction: Epoxy adhesives are used to bond concrete, wood, and other materials.

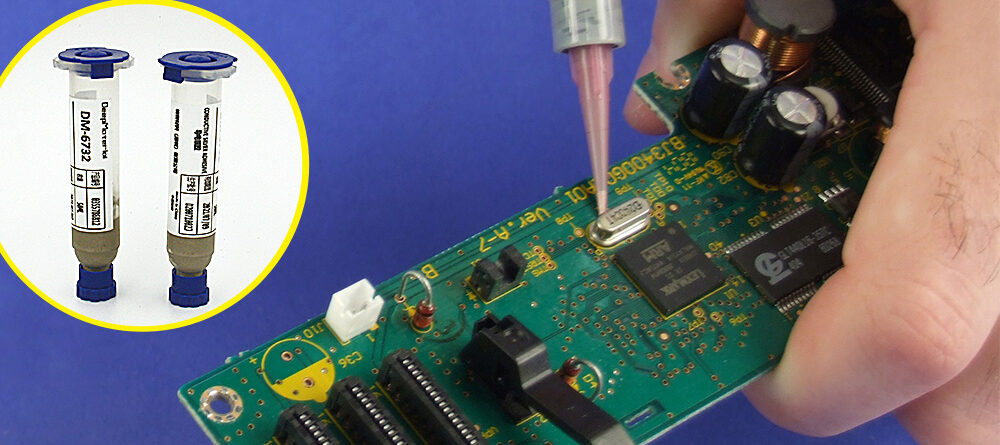

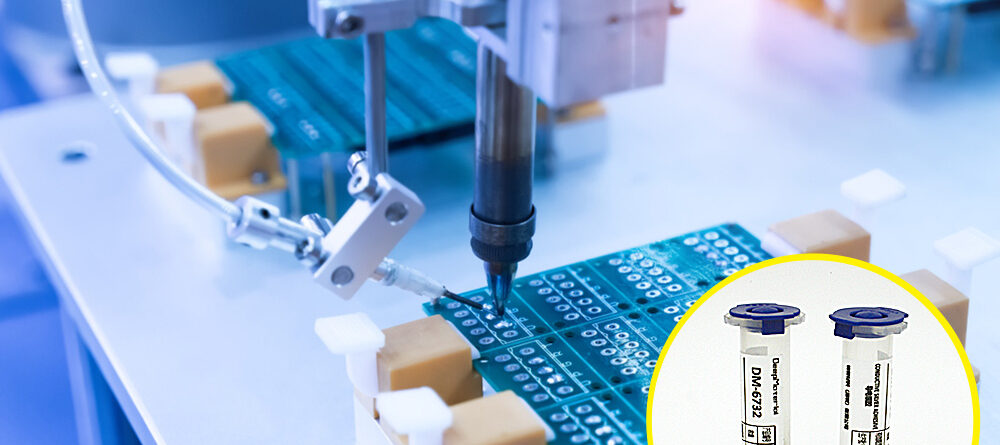

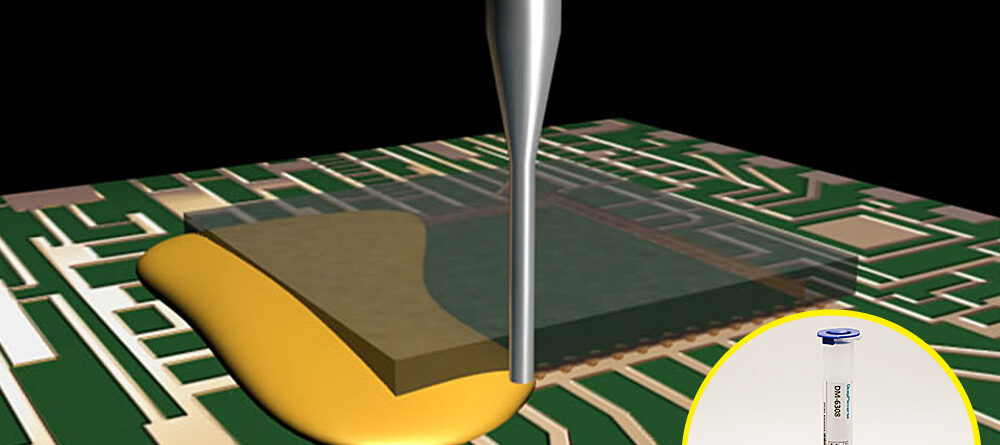

3.Electronics: Epoxy adhesives are bonding components in electronic devices such as circuit boards and sensors.

4.Aerospace: Epoxy adhesives are used for bonding composite materials in the aerospace industry.

5.Marine: Epoxy adhesives bond boats, ships, and other marine vessels.

Benefits of Epoxy Adhesives:

1.High strength: Epoxy adhesives, even in high-stress applications, provide excellent bonding strength.

2.Versatility: Epoxy adhesives can bond with various materials, including metals, plastics, and composites.

3.Chemical resistance: Epoxy adhesives resist various chemicals, including acids, bases, and solvents.

4.Water resistance: Epoxy adhesives are water-resistant and can be used in wet environments.

5.Heat resistance: Epoxy adhesives can withstand high temperatures without losing bonding strength.

Classes of Epoxy Adhesives:

1.Class I: These are general-purpose adhesives that are suitable for bonding a variety of materials.

2.Class II: These high-performance adhesives provide superior bonding strength in demanding applications.

3.Class III: These are specialty adhesives for specific applications, such as bonding composites or plastics.

What is the epoxy adhesive glue used for?

Epoxy adhesives glue are a type of high-performance adhesive that can be used for a wide range of applications, including bonding metals, plastics, ceramics, and other materials. They are known for their high strength, durability, and resistance to heat and chemicals. Some common uses for epoxy adhesives include:

1.Construction: Epoxy adhesive is often used to bond materials like concrete, metal, and wood.

2.Automotive: Epoxy adhesive can be used in the automotive industry to bond parts and repair vehicle damage.

3.Electronics: Epoxy adhesive is used to manufacture electronic devices to bond and encapsulate components and create circuit boards.

4.Aerospace: Epoxy adhesive is commonly used in the aerospace industry for connecting and repairing aircraft components.

5.Marine and boat building: Epoxy adhesives are used in marine and boat building to connect and seal hulls, decks, and other components.

6.Jewelry making: Epoxy adhesive secures stones and metal components in jewelry making.

7.Art and crafts: Epoxy adhesive is often used in art and crafts projects as a strong adhesive for various materials, such as glass, ceramic, and metal.

8.Medical devices: Epoxy adhesives are used to manufacture medical devices for bonding and sealing components and creating biocompatible coatings.

9.Sports equipment: Epoxy adhesives are commonly used in the manufacturing of sports equipment, such as skis, snowboards, and surfboards, for their high strength and durability.

Epoxy adhesives can also be used for household repairs like fixing wall cracks or repairing broken furniture. They are also commonly used in manufacturing sports equipment, such as skis and snowboards, and in constructing composite materials, such as carbon fiber. Epoxy adhesives can be applied in various forms, such as two-part liquid or paste, and cured at room temperature or with heat. Overall, epoxy adhesive is a versatile and robust bonding agent that can be used in various applications across multiple industries.

What is the advantage of epoxy adhesive glue?

Epoxy adhesive glue is a two-component adhesive widely used in various industries due to its superior bonding properties. It is famous for bonding materials that require high strength and durability, such as metals, plastics, and ceramics. This article will discuss the advantages of epoxy adhesive glue and why it is a preferred choice in many applications.

High strength and durability: One of the primary advantages of epoxy adhesive glue is its high strength and durability. Once cured, epoxy adhesive glue forms a strong bond that can withstand heavy loads and resist cracking or breaking. It is also highly resistant to temperature fluctuations, chemicals, and moisture, making it an ideal choice for applications where bonded materials are exposed to harsh environments.

Versatility: Epoxy adhesive glue is versatile and can bond various materials, including metals, plastics, ceramics, and composites. It can also connect dissimilar materials, such as metal to plastic or ceramic to glass, without compromising the strength of the bond. This versatility makes it a preferred choice in many industries, such as aerospace, automotive, and construction.

Easy to use: Epoxy adhesive glue is easy to use and can be applied using various methods, such as a brush, roller, or spray. Depending on the application requirements, it can also be injected into cavities or applied as a paste. The two-component system ensures the adhesive is mixed correctly, resulting in a strong and reliable bond.

Fast curing time: Epoxy adhesive glue has a fast curing time, which means it can be used in applications requiring a quick turnaround time. Depending on the application requirements, the curing time can be accelerated by using heat or a catalyst.

Chemical resistance: Epoxy adhesive glue is highly resistant to chemicals, including acids, alkalis, and solvents. This makes it an ideal choice for applications where the bonded materials are exposed to chemicals, such as in the chemical processing industry.

Epoxy adhesive glue is prevalent in many industries due to its high strength, versatility, ease of use, fast curing time, and chemical resistance. Its superior bonding properties make it a preferred choice for materials that require high strength and durability, such as metals, plastics, and ceramics. If you are looking for a reliable and high-performance adhesive, consider using epoxy adhesive glue for your next project.

What is the disadvantage of epoxy adhesive glue?

Epoxy adhesive glue has several disadvantages, including:

1.Long curing time: Epoxy adhesive glue can take several hours or even days to cure completely, depending on the type and conditions. This can be a disadvantage if a quick fix is needed.

2.Health hazards: Epoxy adhesive glue contains chemicals that can be harmful if inhaled or ingested. Handling the adhesive carefully and following the manufacturer’s instructions for safe use is essential.

3.Limited flexibility: Epoxy adhesive glue is known to be very strong and rigid, which can be a disadvantage when used for applications requiring flexibility or movement.

4.Temperature sensitivity: Epoxy adhesive glue can become brittle and lose its adhesive properties when exposed to high temperatures or extreme cold.

5.Surface preparation: Epoxy adhesive glue requires a clean and dry surface for optimal adhesion. This means that characters may need to be sanded or cleaned before applying the adhesive, which can be time-consuming and labor-intensive.

6.Difficulty in removal: Once cured, epoxy adhesive glue can be challenging to remove from surfaces, making it a poor choice for applications where repair or replacement may be necessary for the future. Removing cured epoxy may require solvents or mechanical tools, which can damage the surface or material being worked on.

7.Not suitable for all material: Epoxy adhesive glue may not be ideal for use with certain materials such as polyethylene, polypropylene, and some types of rubber. This is because epoxy adhesive glue requires a surface that can bond with the adhesive, and these materials do not have the necessary surface properties.

High cost: Epoxy adhesive glue can be more expensive than other types of adhesive, such as cyanoacrylate or PVA glue. This can make it a less attractive option for some applications where cost is a factor.

What is the strongest epoxy adhesive glue for metal to metal?

The strongest epoxy adhesive for metal-to-metal will typically have high bonding strength, excellent resistance to impact, vibration, shock, and high-temperature resistance. The adhesive should also be able to bond a wide range of metal surfaces, including steel, aluminum, and other alloys. Additionally, the adhesive should have a long working time and a fast curing time.

The specific formulation of the strongest epoxy adhesive for metal to metal may vary depending on the application, but it will generally be a two-part adhesive that requires mixing before use. The two parts typically include a resin and a hardener, which react chemically to form a strong bond.

It’s important to note that different types of metal may require different formulations of epoxy adhesive to achieve the strongest bond. For example, aluminum may require an adhesive specifically formulated to bond with its unique surface properties. Therefore, choosing an appropriate epoxy adhesive for the specific metals being connected is essential.

Another factor to consider is the adhesive’s working time and curing time. Some epoxies have longer working times, which can benefit larger or more complex projects, while others have shorter cure times, which can be helpful for quick repairs.

Ultimately, the strongest epoxy adhesive for metal-to-metal bonding will depend on the bonded metals’ specific application and properties. It’s recommended to consult with a manufacturer or expert to select the best adhesive for the job.

The strongest epoxy adhesive for metal-to-metal bonding will have high bonding strength, excellent resistance to impact, vibration, and high temperatures, and can bond a wide range of metal surfaces. Choosing an appropriate adhesive for the specific metals being bonded is essential, as following the manufacturer’s instructions carefully and taking proper safety precautions.

Is epoxy stronger than glue?

In general, epoxy is more robust than regular glue. Epoxy is a two-part adhesive made of resin and a hardener. When these two parts are mixed together, they create a chemical reaction that results in a solid and durable bond.

Epoxy has a higher tensile strength than most types of glue, which means it can withstand more stress and strain without breaking. It is also more resistant to water, heat, and chemicals than regular glue, which makes it a popular choice for industrial and construction applications.

However, the strength of the bond also depends on the materials being bonded and the specific type of glue or epoxy used. Many kinds of glues and epoxies are available, each with particular properties and strengths. So, choosing the right type of adhesive for the job is essential based on the materials and conditions involved.

Additionally, epoxy can take longer to cure and requires a precise mixing process, making it more challenging to use than regular glue. Epoxy also tends to be more expensive than everyday glue.

On the other hand, regular glue is a more general term that includes a wide variety of adhesives, including white glue, wood glue, super glue, and more. The strength and durability of regular glue can vary widely depending on the type of glue used and the materials being bonded.

While epoxy is generally more robust than regular glue and has superior resistance to water, heat, and chemicals, the choice of adhesive depends on the specific materials and conditions involved. It’s essential to consider the properties and strengths of each adhesive before selecting the best one for the job.

In general, both epoxy and regular glue have their strengths and weaknesses. The best adhesive for the job depends on the specific materials and conditions involved. Researching and choosing a suitable adhesive ensures a solid and durable bond.

When to use epoxy adhesive glue?

Here are some everyday situations where epoxy adhesive might be the best choice:

1.Bonding metals: Epoxy is an excellent choice for bonding metals together as it creates a solid and durable bond that can withstand heavy loads and high temperatures.

2.Filling gaps and cracks: Epoxy can be used to fill gaps and cracks in a wide range of materials, including wood, plastic, and concrete. Once cured, the epoxy creates a strong, waterproof seal.

3.Building and repairing boats: Epoxy is often used in boat building and repair due to its ability to withstand exposure to water and harsh marine environments.

4.Electronics and electrical systems: Epoxy is used in manufacturing electronics and electrical systems because it insulates against electrical current.

5.Automotive repair: Epoxy can be used to repair dents and cracks in automotive bodies and to bond various parts together.

6.Waterproofing: Epoxy adhesive can create a waterproof seal, making it ideal for applications where moisture resistance is necessary, such as boat repairs or sealing a leaky pipe.

7.Construction and home repair: Epoxy can repair and bond various materials commonly found in homes, including concrete, wood, and tile

8.DIY projects: Epoxy adhesive can be used in various DIY projects, such as repairing furniture, fixing household items, or bonding different materials to create custom projects.

9.Plumbing repairs: Epoxy can seal leaks in pipes, joints, and fixtures, making it a reliable option for plumbing repairs.

10.Outdoor applications: Epoxy is resistant to UV radiation, weather, and moisture, making it suitable for outdoor applications such as repairing outdoor furniture, sealing cracks in concrete, or bonding outdoor structures.

11.Metal and plastic bonding: Epoxy adhesive is commonly used for bonding metal and plastic materials, providing a solid and durable bond that can withstand stress and impact.

12.Jewelry making: Epoxy resin is often used to create clear, glossy coatings on pendants, charms, and other jewelry components.

13.Medical applications: Epoxy is used in the manufacturing of medical devices, as it is biocompatible and can bond various materials used in medical equipment and implants.

Related Sources About Epoxy Adhesive Glue:

Best Epoxy Adhesive Glue For Automotive Plastic To Metal

Low temperature curing epoxy adhesive for sensitive devices

Epoxy Adhesive for Plastic: A Comprehensive Guide

Electric Motor Magnet Bonding Epoxy Adhesive Glue And How It Provides The Best Maintenance

What is epoxy adhesive used for?

Everything You Need to Know About One Component Epoxy Adhesive

About Electronic Epoxy Adhesive Glue Manufacturer

Deepmaterial is reactive hot melt pressure sensitive adhesive manufacturer and supplier, manufacturing one component epoxy underfill adhesives, hot melt adhesives glue, uv curing adhesives,high refractive index optical adhesive, magnet bonding adhesives, best top waterproof structural adhesive glue for plastic to metal and glass, electronic adhesives glue for electric motor and micro motors in home appliance.

HIGH QUALITY ASSURANCE

Deepmaterial is determined to become a leader in the electronic adhesives industry, quality is our culture!

FACTORY WHOLESALE PRICE

We promise to let customers get the most cost-effective epoxy adhesives products

PROFESSIONAL MANUFACTURERS

With electronic adhesives as the core, integrating channels and technologies

RELIABLE SERVICE ASSURANCE

Provide epoxy adhesives OEM, ODM, 1 MOQ.Full Set of Certificate

Epoxy Flame Retardant Adhesive

Epoxy Flame Retardant Adhesive Epoxy flame retardant adhesives are a specialized category of adhesives that integrate the superior bonding capabilities of epoxy resins with additives that enhance fire resistance. Epoxy resins, derived typically from bisphenol A and epichlorohydrin, are celebrated for their exceptional adhesion, mechanical strength, and resistance to chemicals....

Safe Fireproof Glue for Home Use

Safe Fireproof Glue for Home Use In today’s homes, safety is a top priority, especially when it comes to the materials we use for construction, repairs, or DIY projects. One often overlooked but critical component is the adhesive or glue employed in these tasks. While most glues are designed for...

Flame Retardant Adhesive for Circuit Boards

Flame Retardant Adhesive for Circuit Boards In the fast-paced world of modern electronics, where circuit boards power everything from smartphones to vehicle control systems, safety and reliability are paramount. Flame retardant adhesives for circuit boards are specialized bonding agents designed to secure components, provide insulation, and prevent fire hazards in...

Exploration of the Limitations and Complementarity of Fire Retardant Materials Testing Methods

Exploration of the Limitations and Complementarity of Fire Retardant Materials Testing Methods In the fields of materials science and fire safety, fire retardant materials play a crucial role. To evaluate their performance, international and national standards such as ISO, ASTM, and GB have been established. Commonly used testing methods include...

Synergistic Enhancement Mechanism of Gas-Phase, Condensed-Phase, and Heat-Exchange Interruption Flame Retardant Mechanisms

Synergistic Enhancement Mechanism of Gas-Phase, Condensed-Phase, and Heat-Exchange Interruption Flame Retardant Mechanisms With the widespread application of polymer materials in fields such as construction, electronics, and transportation, the flame retardant properties of materials have become increasingly important. A single flame retardant mechanism often struggles to meet complex flame retardant requirements,...

How to More Accurately Evaluate the Comprehensive Fireproof Effect of Fireproof Adhesives by Simulating Actual Fire Scenarios

How to More Accurately Evaluate the Comprehensive Fireproof Effect of Fireproof Adhesives by Simulating Actual Fire Scenarios Fireproof adhesives play a critical role in fire safety across numerous fields, including construction, electronics, and transportation. Accurately evaluating the comprehensive fireproof effect of fireproof adhesives is of paramount importance for ensuring human...