Tips To Handle Potting Material For PCB To Get Best Results

Tips To Handle Potting Material For PCB To Get Best Results

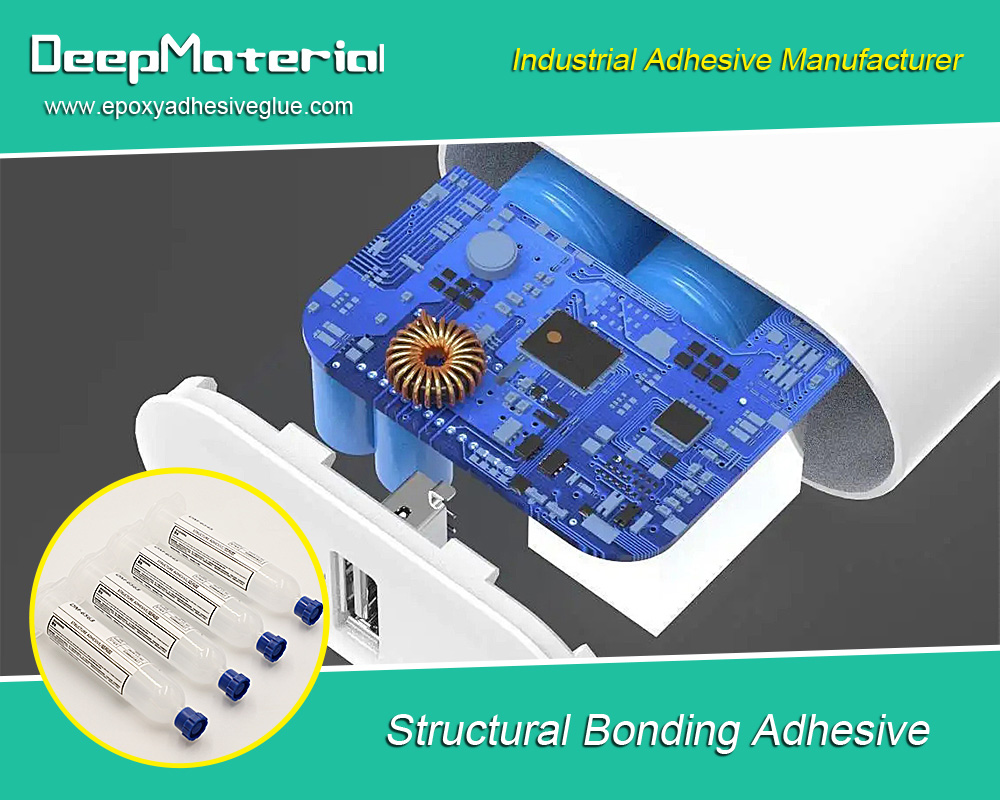

Printed circuit boards are crucial in electronics. They serve as the brain for the electronics, and hence when they are dysfunctional or damaged, the device is as good as dead. The boards need protecting, whichever means possible, because only when they are in good shape will the electronics function and perform effectively and last a long time doing so.

Protective resin layers protect PCBs using methods such as conformal coating and potting. While conformal coating creates a thin film layer on the circuit boards, potting encloses the boards in a case surrounded by a thick protective resin layer. The layer can be rigid or soft, as the board components command. Different compounds are used to achieve the desired results and come in varying hardness levels to match application needs.

Epoxy, polyurethane, and silicone are the major potting materials used on PCBs. Epoxy offers a rigid, durable layer, whereas silicone offers a more flexible but protective layer. The sensitivity of the circuit board determines which material to use. They also come in different colors, but clear versions of the resins are more popular because they keep the circuit boards visible and are easy to keep an eye on or do repairs on.

Getting the right potting material for PCB is the first step to good results. Whereas the properties of the materials remain the same across the board, the quality you get will depend on the brand you settle for. Where you source your potting materials is therefore important, and DeepMaterial is one of the best manufacturers and suppliers you can choose when looking for high quality products. But even after you get the right product, you should know the right way to use it to get desired results, and the tips below can help the process.

- Always find a well-ventilated area to do your potting from. Alternatively, you can get extraction and ventilation systems to ensure enough air circulating. This is important because some compounds give off hazardous fumes during application and as they cure.

- Use the manufacturer’s guide for health and safety measures. You might need safety glasses and protective gloves to handle even the simplest formulations. It also helps to follow the product instructions for use.

- When handling the hardener and resin, ensure you protect both from moisture, as it can adversely affect potting results. Defects on the protective layer will mean repeating the process, which can be costly and time-wasting. You are better off getting it on the first attempt.

- Mix resin material if you have not used it for several days because, with time, the compounds separate, with the heavier ones settling at the bottom and lighter ones rising to the top. Without proper mixing, your ratio and potting weight will be affected.

- For high production lines, create batches and allow full settings before checking whether the results are satisfactory. Such tests can go a long way in saving costs you would have otherwise used, redoing poor potting results.

- Before starting the potting process, pre-fill container tanks and give enough time for the resin material to heat and achieve optimum temperature. It is a simple way of enjoying easy flow, hence more consistent pots.

For more about tips to handle potting material for pcb to get best results,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/the-major-types-of-encapsulating-and-potting-compounds-for-pcb/ for more info.