The Role of Industrial Appliance Adhesive in Bonding Different Materials

The Role of Industrial Appliance Adhesive in Bonding Different Materials

Industrial appliance adhesive plays a crucial role in bonding different materials together in various industries. Whether it is in the automotive, construction, electronics, aerospace, or medical industry, the use of adhesive is essential for creating strong and durable bonds. This article will provide an in-depth understanding of industrial appliance adhesive, its properties, advantages, applications, and challenges.

Understanding the Bonding Process of Different Materials

The bonding process involves joining two or more materials together using an adhesive. The adhesive acts as a medium that fills the gaps between the materials and creates a strong bond when it cures or hardens. The success of the bonding process depends on several factors, including the type of adhesive used, the surface preparation of the materials, and the environmental conditions during bonding.

The type of materials that can be bonded using industrial appliance adhesive is vast. It can be used to bond metals such as steel, aluminum, and copper, as well as plastics such as ABS, PVC, and polycarbonate. Additionally, it can bond ceramics, composites, and even dissimilar materials. This versatility makes industrial appliance adhesive a popular choice in various industries.

Advantages of Using Industrial Appliance Adhesive

There are several advantages to using industrial appliance adhesive in bonding different materials. Firstly, it is cost-effective compared to other joining methods such as welding or mechanical fastening. Adhesive bonding eliminates the need for additional parts or equipment, reducing production costs.

Secondly, industrial appliance adhesive provides a strong and durable bond that can withstand the stresses and strains experienced in industrial applications. It distributes the load evenly across the bonded area, resulting in a stronger joint compared to other joining methods.

Thirdly, industrial appliance adhesive is resistant to environmental factors such as temperature, humidity, and chemicals. This makes it suitable for use in various industries where the bonded materials may be exposed to harsh conditions.

Lastly, industrial appliance adhesive is easy to apply. It can be applied using various methods such as manual application, spray application, or automated dispensing. This flexibility in application methods allows for efficient and precise bonding.

Applications of Industrial Appliance Adhesive in Various Industries

Industrial appliance adhesive finds applications in various industries due to its versatility and strong bonding properties. In the automotive industry, it is used for bonding components such as body panels, interior trims, and structural parts. The adhesive provides a lightweight and durable bond that improves fuel efficiency and reduces noise and vibration.

In the construction industry, industrial appliance adhesive is used for bonding materials such as glass, metal, and concrete. It is used in applications such as curtain walling, cladding, and flooring. The adhesive provides a strong bond that can withstand the structural loads and environmental conditions in buildings.

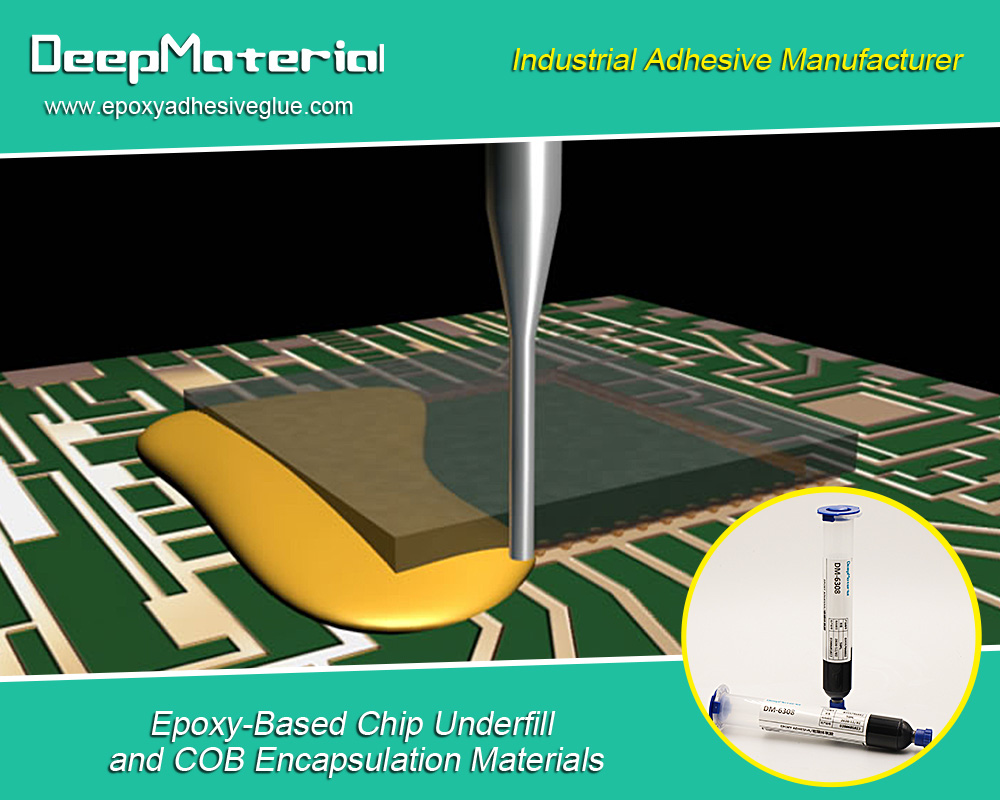

In the electronics industry, industrial appliance adhesive is used for bonding components such as circuit boards, displays, and sensors. The adhesive provides electrical insulation and protection against moisture and contaminants.

In the aerospace industry, industrial appliance adhesive is used for bonding components such as aircraft panels, wings, and interiors. The adhesive provides a lightweight and durable bond that can withstand the extreme conditions experienced in aerospace applications.

In the medical industry, industrial appliance adhesive is used for bonding components such as medical devices, prosthetics, and implants. The adhesive provides a biocompatible and sterile bond that is safe for use in medical applications.

Importance of Proper Surface Preparation Before Bonding

Proper surface preparation is crucial before bonding materials using industrial appliance adhesive. It involves cleaning and treating the surfaces to ensure optimal adhesion. Surface preparation removes contaminants such as dirt, grease, and oils that can interfere with the bonding process.

Proper surface preparation is important because it improves the adhesion strength and durability of the bond. It also ensures that the adhesive can wet out and spread evenly on the surfaces, resulting in a stronger bond. Additionally, surface preparation helps to remove any surface irregularities or roughness that can affect the bond strength.

There are several methods of surface preparation, including cleaning with solvents, sanding or abrading the surfaces, and applying primers or adhesion promoters. The method used depends on the type of materials being bonded and the specific requirements of the adhesive.

Maintenance and Repair of Bonded Materials

Maintenance and repair of bonded materials are important to ensure the longevity and performance of the bond. Regular inspection and maintenance can help identify any issues or damage to the bond early on, allowing for timely repairs.

Methods of maintenance and repair depend on the specific materials and adhesive used. In some cases, the damaged area can be repaired by applying additional adhesive or using a compatible adhesive to reinforce the bond. In other cases, the damaged area may need to be replaced or repaired using other methods such as welding or mechanical fastening.

Regular cleaning and inspection of the bonded materials can help prevent issues such as contamination or degradation of the bond. It is important to follow the manufacturer’s recommendations for maintenance and repair to ensure the integrity of the bond.

Future Developments in Industrial Appliance Adhesive Technology

The future of industrial appliance adhesive technology looks promising, with ongoing developments in materials and formulations. Researchers are constantly working on developing new adhesives that offer improved bonding properties and performance.

One area of development is in the use of new materials such as nanomaterials and bio-based materials. These materials offer unique properties such as enhanced strength, flexibility, and biocompatibility. They also provide opportunities for developing adhesives that are more environmentally friendly and sustainable.

Another area of development is in improving the bonding properties of adhesives. Researchers are working on developing adhesives with faster curing or drying times, higher bond strengths, and improved resistance to environmental factors. These advancements will further enhance the performance and durability of bonded materials.

Efficiency and ease of application are also areas of focus in adhesive technology. Researchers are developing adhesives that can be applied more efficiently and precisely, reducing waste and improving productivity. Additionally, advancements in dispensing and application equipment are making it easier for manufacturers to apply adhesives in automated production processes.

Conclusion

In conclusion, industrial appliance adhesive plays a crucial role in bonding different materials together in various industries. It offers several advantages such as cost-effectiveness, strong and durable bonds, resistance to environmental factors, and ease of application. Proper surface preparation before bonding is important to ensure optimal adhesion, and regular maintenance and repair of bonded materials are necessary to ensure their longevity and performance.

The future of industrial appliance adhesive technology looks promising, with ongoing developments in materials, formulations, and application methods. These advancements will further enhance the performance and durability of bonded materials, making industrial appliance adhesive an even more essential tool in various industries.

For more about choosing the Role of Industrial Appliance Adhesive in Bonding Different Materials, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.