PCB potting compound choices for electronic components from potting material manufacturers

PCB potting compound choices for electronic components from potting material manufacturers

In many electronic components, it is important to achieve reliable and long-term protection. It is one of the ways in which premature failure can be prevented. The rising circuit density and small systems have led to much high operating temperatures. This has made it necessary to find the best heat dissipation solutions.

Methods used

Different technologies can be used to protect electronic components, especially sensitive ones. This includes:

- Casting: in this case, the hardenable or catalyzed liquid are poured into a mold. This cast part will be shaped like the mold, which can then be reused.

- Potting: this is where a hardenable or a catalyzed liquid is poured into a housing or shell, which remains a part of the whole unit.

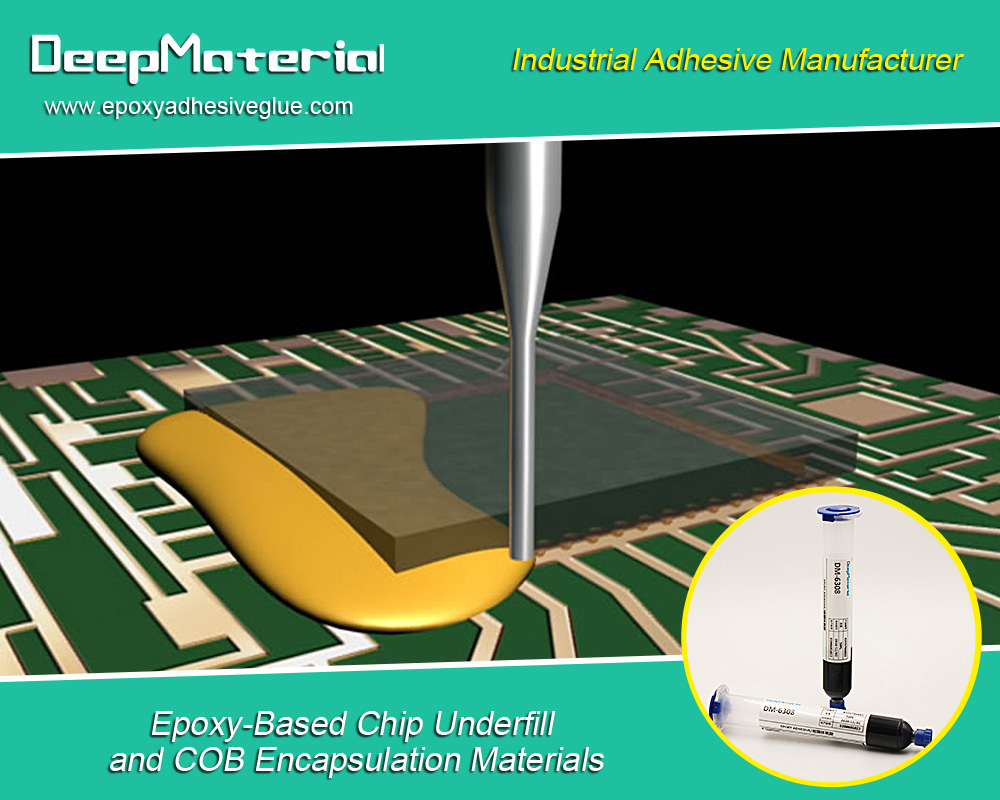

- Encapsulation: this involves a thin shell or protective coating that is laid around an assembly or component. Instead of a permanent container, a mold is used. When you remove the mold, the cured resin remains on the outside.

- Sealing: this is where a barrier is provided on the surface of the container joint housing devices

- Impregnation: in this case, the part is immersed completely in a liquid to ensure the interstices are wetted or soaked.

Potting materials

Hardeners and resins are needed in encapsulation and potting. Resins are used in the electrical and electronics industries. The main categories are polyesters, hot melts, silicone, urethane, and epoxy. This depends on the chemical types.

Epoxy: epoxy has good thermal properties that allow it to work where there are high temperatures. Sometimes, epoxy can be formulated so that it can be exposed to much higher temperatures. These compounds are stable and predictable throughout the whole process. They offer very good resistance to chemicals except for acids. They offer the best adhesion and strength on porous and non-porous surfaces.

Urethanes: urethanes have a wide range of characteristics related to hardness. They are used on printed circuit boards and can be customized to speed up processes. They can be used in applications that need heat resistance. They are chemical resistant as well. If you want a flexible bond, urethane is the ideal option for you.

Silicone: This is a compound that can be adaptable to low and higher temperatures as well. Many applications match this compound. They give a flexible and soft bond that can be cured by UV. Silicone has good solvent resistance. One of the main issues with silicone is the high cost and the fact that it does work well with some plastics.

Hot melts: these are very easy to use, and they set fast. They are a good choice for gap-filling. They can be removed for purposes of rework and repair. They have a low resistance to heat but great solvent resistant. These can be polyolefin, polyurethane, or polyamide-based.

Polyester resins: unsaturated polyester resins are commonly used in electrical potting applications. The mechanical characteristics are rigid to flexible. The temperature and chemical resistance of the materials is fair. They have good adhesion to metals as well.

Buying the best

To access the highest quality potting compounds, work with DeepMaterial. We have a wide range of compounds and other products that can be used in industrial and DIY projects. We can easily custom-make solutions to meet your specifications.

For more about the PCB potting compound choices for electronic components from potting material manufacturers,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/pcb-potting-material/ for more info.