What Are The Restrictions Of SMD Red Glue?

What Are The Restrictions Of SMD Red Glue?

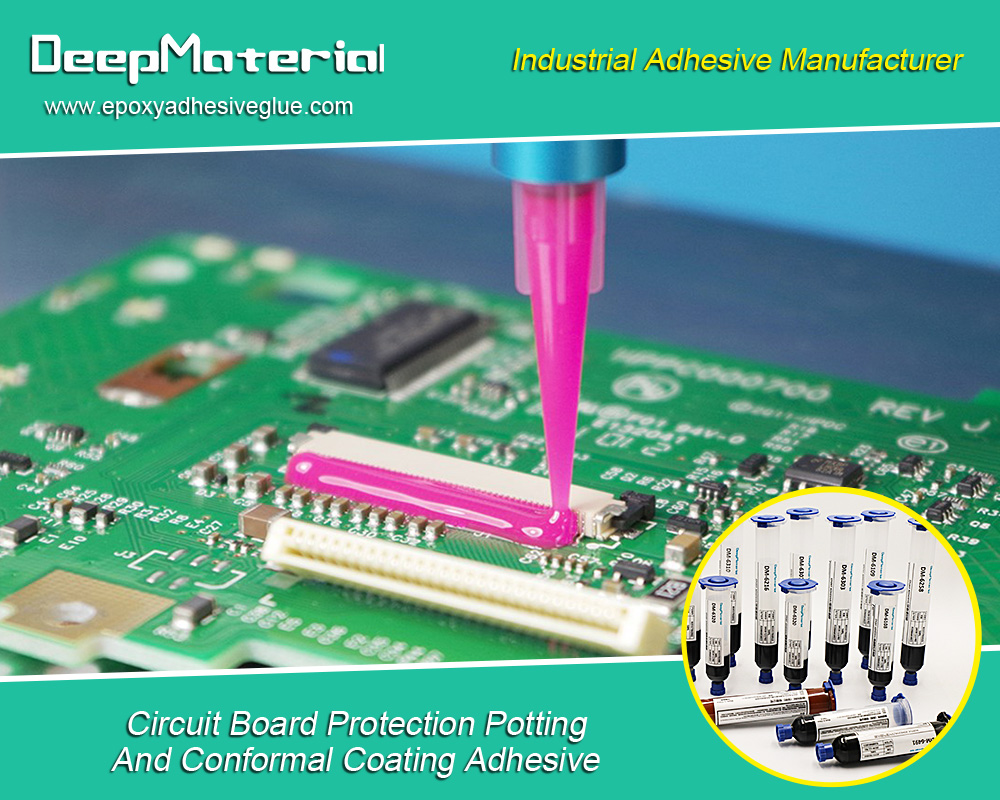

The SMD red glue is the most widely used adhesive for fixing small parts on circuit boards. It is used to connect electronic components with PCBs and other devices. This type of glue is necessary because it does not contain any toxic substances, and its cost is low compared with different types of glue based on its performance level.

The main restrictions of SMD red glue are its high-temperature resistance and low melting point. These properties make the glue unsuitable for use in high-temperature environments or for applications where the temperature may exceed the melting point of the glue. In addition, the glue is not resistant to solvents and chemicals, which can attack and break down the bond between the adhesive and the surfaces it is bonding.

Introduction to SMD Red Glue

SMD red glue is a type of conductive adhesive that is often used in the electronics industry. This glue is designed to be used with surface-mount devices (SMDs) and allows for a strong connection between the device and the substrate. However, there are some restrictions on how this glue can be used.

One restriction of SMD red glue is its operating temperature range. This glue can only be used within a specific temperature range, typically -40°C to +150°C. If the temperature gets too high, the adhesive will degrade and may not provide a secure connection.

Another restriction is how long SMD red glue takes to cure. This adhesive can take up to 24 hours to fully heal, so it’s important to plan when using it. If you need a quick fix, other adhesives may work better for your needs.

Finally, SMD red glue has a limited shelf life. Once this adhesive is mixed, it has to be used within a few hours, or it will start to harden and become unusable. This means that you must be prepared before starting your project and ensure you have enough adhesive for your needs.

What Is The Difference Between SMD Red Glue And Other Types Of Adhesives?

When choosing an adhesive for your project, it is essential to understand the difference between various types of bonds. SMD red glue is an adhesive designed explicitly for surface-mount devices (SMDs). Other types of adhesives may be less effective or may even damage the SMD.

SMD red glue has several advantages over other types of adhesives. It is specifically designed to bond with SMDs, so it will not damage the delicate components. It is also solid and resists thermal cycling. However, there are some restrictions on using SMD red glue.

The most significant restriction is that it can only be used on clean, dry surfaces. Any grease, oil, or dirt will prevent the adhesive from bonding properly. The cover also needs to be free of any dust or debris. If the surface is not clean enough, the adhesive will not bond correctly and could cause damage to the SMD.

Another restriction is that SMD red glue can only be used on flat surfaces. Curved or uneven surfaces can make it challenging to apply the adhesive evenly and could lead to an inconsistent bond.

Finally, SMD red glue has a limited working time. Once the adhesive has been applied, it must be left undisturbed for at least 24 hours to cure properly. During this time, the area should not be exposed to dust or dirt as this can contaminate the curing process.

How To Clean SMD Red Glue Off A Surface

There are a few restrictions to knowing about SMD red glue before using it. For one, it is not recommended for use on surfaces exposed to sunlight or extreme temperatures. Additionally, while SMD red glue can be used on porous and non-porous surfaces, it works best on non-porous surfaces like glass or metal.

If you need to clean SMD red glue off a surface, the best way to do so is with acetone or isopropyl alcohol. Apply either of these solvents to a cotton ball or rag and rub away at the dried red glue until it comes off. You may need to repeat this process a few times to get all the glue off, but eventually, you should be left with a clean surface.

If you don’t have any acetone or isopropyl alcohol, you can try using a razor blade to scrape the red glue off. This method will take a bit more time and effort, but it will get the job done if you don’t have other options.

Once you’ve removed all of the SMD red glue from the surface, clean the area with soap and water to remove any residual solvent.

Safety Precautions For SMD Red Glue

When working with SMD red glue, it is essential to take some safety precautions to avoid accidents or injuries. Here are some safety tips to keep in mind:

1. Always wear gloves when handling SMD red glue. The chemicals in the adhesive can be harmful if they come into contact with your skin.

2. If you get any SMD red glue on your skin, wash it off immediately with soap and water.

3. Avoid inhaling the fumes from SMD red glue. Use a respirator or work in a well-ventilated area if possible.

4. Keep SMD red glue away from children and pets. The chemicals in the adhesive can be harmful if ingested or inhaled.

Conclusion

In conclusion, SMD red glue has a wide range of applications and is very versatile. However, there are some restrictions that you should be aware of before using them. It is not suitable for use on porous surfaces or in areas with dust or dirt. In addition, it should not be used in direct sunlight or on hot surfaces, as this can cause the glue to deteriorate.

For more about SMD red glue,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/smt-epoxy-adhesives/ for more info.