How Epoxy Flame Retardant Adhesives Are Redefining Safety in Modern Manufacturing

How Epoxy Flame Retardant Adhesives Are Redefining Safety in Modern Manufacturing

The Invisible Threat in Everyday Products

Consider the smartphone in your hand, the electric vehicle you drive, or the circuit board powering your home appliances. Within these marvels of modern engineering lies an often-overlooked but critical safety component: the adhesive that holds them together. For decades, standard epoxy adhesives have provided excellent structural bonds, but they come with a dangerous secret—many are highly flammable, acting as potential fuel sources in the event of a thermal incident. This inherent flammability has been a silent partner to countless product failures, electrical fires, and tragic losses.

The call to reject these “flammable hazards” is not just a matter of regulatory compliance; it is a fundamental ethical and engineering imperative. The response to this challenge has been the development and refinement of Epoxy Flame Retardant Adhesives. These advanced materials represent a paradigm shift, transforming a potential liability into a robust line of defense. This article delves into the world of these specialized adhesives, exploring the science behind their fire-resistant properties, their key formulations, the rigorous testing they undergo, and their critical applications across industries from aerospace to consumer electronics. By understanding their capabilities, manufacturers can move beyond mere adhesion to integrating active safety at the molecular level.

1. The Flammability Problem: Why Standard Epoxies Are a Fire Risk

To appreciate the innovation of flame-retardant epoxies, one must first understand why their conventional counterparts are so vulnerable to fire.

1.1 The Chemical Composition of Combustion

Standard epoxy flame retardant adhesives are typically composed of carbon, hydrogen, and oxygen, arranged in polymer chains derived from petroleum-based precursors like bisphenol A (BPA) and epichlorohydrin. When exposed to sufficient heat—from an electrical short circuit, an external flame, or overheating components—this organic matrix undergoes thermal decomposition. This process, known as pyrolysis, breaks down the long polymer chains into smaller, volatile fuel fragments.

These fragments then mix with atmospheric oxygen, and upon reaching a specific ignition temperature, they undergo a self-sustaining combustion reaction. This reaction releases immense heat, which further decomposes the surrounding epoxy, creating a vicious cycle of burning. The result is not just the failure of the adhesive bond but also the release of intense heat, dense smoke, and often toxic gases, exacerbating the danger.

1.2 The Domino Effect in Electronic and Structural Applications

The risk is particularly acute in specific scenarios:

-

Electronics: A faulty capacitor or a power surge on a printed circuit board (PCB) can generate localized temperatures exceeding 500°C. A standard epoxy used for chip encapsulation or structural bonding can ignite, transforming a small component failure into a board-wide conflagration.

-

Transportation: In the confined spaces of an aircraft, train, or electric vehicle, a fire can be catastrophic. Electrical panels, battery housing assemblies, and interior components bonded with flammable adhesives can contribute to the rapid spread of fire and smoke.

-

Construction: While building codes are strict, electrical fixtures, ventilation systems, and other building elements that use adhesives in their assembly can become fire propagation paths if the adhesive itself is flammable.

This inherent vulnerability created an urgent need for a new class of adhesives that could provide all the benefits of epoxies—strong adhesion, chemical resistance, and durability—without the fatal flaw of flammability.

2. The Science of Safety: How Flame Retardancy Works

Flame retardant epoxy adhesives are engineered to interrupt the combustion cycle at one or more of its critical stages: heating, decomposition, ignition, or flame spread. They achieve this through two primary mechanistic approaches: Vapor Phase Inhibition and Condensed Phase Action.

2.1 Vapor Phase Inhibition (The Gas Scavenger)

This mechanism relies on additives that, when heated, release chemically active species into the flame zone. The most common examples are halogen-based flame retardants (Bromine and Chlorine).

-

The Process: When the epoxy decomposes under heat, the halogenated compounds release halogen radicals (e.g., Br• or Cl•) into the gas phase.

-

The “Scavenging” Action: These highly reactive radicals interfere with the high-energy H• and OH• radicals in the flame that are essential for the combustion chain reaction. They form more stable molecules like HBr or H₂O, effectively “scavenging” the free radicals and quenching the flame’s propagation.

-

Advantage and Disadvantage: Halogenated systems are highly effective at low loadings. However, there is growing regulatory and environmental pressure against them due to the potential generation of toxic and corrosive dioxins and furans during combustion.

2.2 Condensed Phase Action (The Protective Char)

This mechanism works by creating a physical barrier on the material’s surface. The most prominent examples here are phosphorus-based and inorganic hydrate flame retardants.

-

Phosphorus-based Systems: Upon heating, phosphorus compounds decompose to form phosphoric acid and its derivatives. This acidic layer promotes the dehydration and cross-linking of the polymer, catalyzing the formation of a swollen, thermally stable carbonaceous layer known as char. This char acts as a physical insulator, shielding the underlying virgin material from heat and oxygen and preventing the release of further flammable volatiles.

-

Inorganic Hydrates (e.g., Aluminum Trihydroxide (ATH), Magnesium Hydroxide): These additives function through endothermic cooling. When heated, they decompose, releasing water vapor (H₂O). This reaction absorbs a significant amount of heat from the surroundings, effectively cooling the polymer below its decomposition temperature. The released water vapor also dilutes the flammable gases in the vapor phase. While highly eco-friendly, they often need to be added in high loadings (50-60% by weight), which can impact the adhesive’s mechanical and flow properties.

Modern high-performance flame retardant epoxies often use a synergistic approach, combining different mechanisms for enhanced performance. A common and effective synergy is between halogenated compounds and antimony trioxide (Sb₂O₃), which together form antimony halides in the vapor phase, dramatically increasing flame-inhibiting efficiency.

3. Key Formulations and Material Properties

Flame retardant epoxies are not a one-size-fits-all solution. They are formulated to meet specific performance criteria for different applications.

3.1 Halogenated vs. Halogen-Free (The Critical Divide)

The most significant categorization in the industry is between Halogenated and Halogen-Free (often called “Green”) Flame Retardants.

-

Halogenated Flame Retardant Epoxies:

-

Composition: Contain bromine or chlorine compounds.

-

Pros: High efficiency at low concentrations, minimal impact on the epoxy’s original mechanical properties (viscosity, strength), and cost-effectiveness.

-

Cons: Face increasing restrictions (e.g., RoHS, REACH); can produce corrosive and toxic smoke when burned.

-

Use Case: Still prevalent in applications where regulations allow and where performance-to-weight ratio is critical.

-

-

Halogen-Free Flame Retardant (HFFR) Epoxies:

-

Composition: Rely on phosphorus, nitrogen, inorganic hydrates (ATH, MDH), or mineral fillers like huntite/hydromagnesite.

-

Pros: Environmentally preferable, produce less toxic and less corrosive smoke, and are increasingly mandated by international regulations and corporate sustainability policies.

-

Cons: Often require higher filler loadings, which can increase viscosity, reduce flowability, and slightly compromise mechanical strength. They can also be more expensive.

-

Use Case: The fastest-growing segment, driven by the electronics, automotive, and green building sectors.

-

3.2 Performance Beyond Flame Retardancy

A flame retardant adhesive must still perform its primary duty: bonding. Key properties include:

-

Thermal Conductivity: For applications in power electronics, epoxies are often formulated to be thermally conductive (to dissipate heat away from components) while also being flame retardant.

-

Electrical Insulation: They must maintain high dielectric strength to prevent electrical shorts.

-

Glass Transition Temperature (Tg): The temperature at which the polymer transitions from a rigid glassy state to a rubbery one. A high Tg is crucial for applications that experience operational heating.

-

Cure Schedule: From fast-curing, room-temperature systems for high-volume manufacturing to heat-cured systems for maximum performance.

4. The Litmus Test: Standards and Certifications for Flame Retardant Adhesives

The claim of “flame retardancy” is meaningless without standardized, third-party validation. Several key tests define the performance thresholds.

4.1 UL 94: The Gold Standard for Flammability of Plastic Materials

Underwriters Laboratories (UL) 94 is the most widely recognized test for flammability. It classifies materials based on their ability to extinguish a flame after being ignited. Key ratings for adhesives include:

-

UL 94 V-0: The highest rating. The specimen extinguishes within 10 seconds after two flame applications, with no flaming drips that ignite cotton below.

-

UL 94 V-1: The specimen extinguishes within 30 seconds after two flame applications, with no flaming drips.

-

UL 94 V-2: Similar to V-1, but allows for flaming drips.

-

UL 94 HB: The lowest rating, indicating a “Horizontal Burn” material that burns slowly.

For electronics, achieving a UL 94 V-0 rating is often a non-negotiable requirement.

4.2 Other Critical Standards

-

Limiting Oxygen Index (LOI): LOI measures the minimum concentration of oxygen in an oxygen/nitrogen mixture required to support the flaming combustion of a material. A higher LOI indicates a more flame-retardant material. Standard epoxies may have an LOI of ~19%, while flame-retardant versions can exceed 30%.

-

Glow-Wire Test (IEC 60695-2-12): This test simulates thermal stresses caused by overheating components by pressing a hot wire against the material. It is crucial for consumer appliance certifications.

-

Aerospace (FAR 25.853) & Railway (EN 45545): These industries have their own brutal sets of tests governing heat release, smoke density, and toxicity, pushing adhesive formulations to their absolute limits.

5. Application Spotlight: Where Safety is Bonded In

The use of flame retardant epoxy adhesives is critical in high-risk, high-reliability industries.

-

Electronics & Electrical:

-

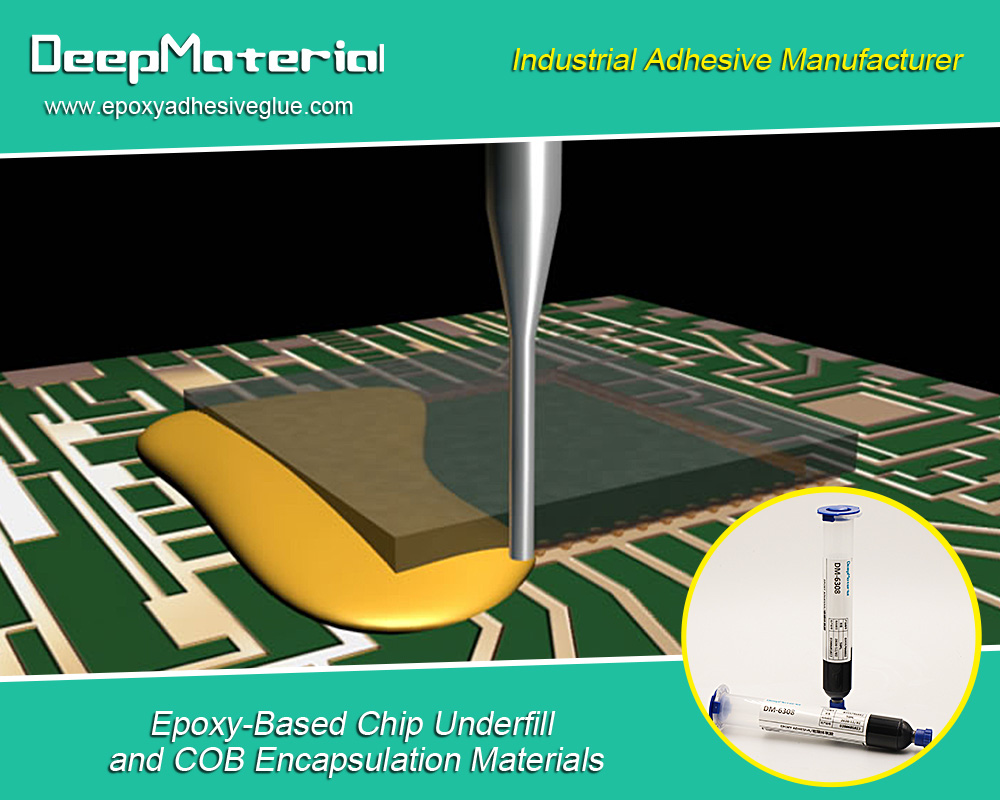

PCB Potting and Encapsulation: Protects sensitive components from moisture, dust, and physical damage, while ensuring a local electrical fault doesn’t start a fire.

-

Transformer and Inductor Bonding: Secures windings and cores in power conversion equipment that inherently generates heat.

-

Battery Pack Assembly for EVs: Bonds cells into modules and modules into packs, where thermal runaway in one cell must not be allowed to propagate.

-

-

Transportation:

-

Aerospace: Used in bonding interior panels, cable harnesses, and electronic enclosures to meet stringent fire safety standards for cabin materials.

-

Automotive: Critical in bonding components within the engine bay, electrical control units (ECUs), and lighting systems.

-

Rail: Used throughout a train’s interior and electrical systems to comply with rigorous fire safety regulations like EN 45545.

-

-

Construction & Infrastructure:

-

Bonding of Insulated Panels: In commercial buildings, the adhesives used in structural insulated panels (SIPs) must not contribute to fire spread.

-

LED Lighting Assemblies: High-power LEDs generate significant heat; the thermal management adhesives used must also be flame retardant.

-

6. The Future of Flame Retardant Epoxy Adhesives

The evolution of these materials is driven by three powerful trends:

-

The Halogen-Free Mandate: The push for “greener” chemistry will continue to accelerate, driving innovation in more efficient phosphorus, nitrogen, and silicon-based systems that perform as well as their halogenated predecessors without the environmental baggage.

-

Nano-Technology: The incorporation of nano-scale fillers like nanoclay, carbon nanotubes, or graphene offers a path to high flame retardancy at very low loadings. These materials can form exceptional barrier networks within the epoxy, improving char strength and reducing heat release without sacrificing mechanical properties.

-

Bio-based Epoxies: Research into epoxy resins derived from renewable sources like plant oils is ongoing. The challenge is to incorporate effective flame retardancy into these new, sustainable polymer backbones.

Conclusion: An Imperative for Modern Engineering

The era of accepting “flammable hazards” as an unavoidable cost of strong adhesion is over. Epoxy flame retardant adhesives represent a mature, sophisticated, and essential technology that embeds proactive safety into the very fabric of our most advanced products. The choice to specify a flame retardant adhesive is no longer just an engineering decision; it is a commitment to product integrity, user safety, and regulatory compliance.

By understanding the science, the standards, and the applications, manufacturers can make informed choices to reject the old vulnerabilities. In the demanding landscape of modern manufacturing, where failure is not an option, the bond must not only hold—it must also protect. Flame retardant epoxy adhesives deliver on both fronts, ensuring that the products we rely on are not only well-built but are also fundamentally safer.

For more about how epoxy flame retardant adhesives are redefining safety in modern manufacturing, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.