Can a Glue Really Be Fireproof? The Science Behind The Super Glue

Can a Glue Really Be Fireproof? The Science Behind The Super Glue

In our daily lives, we reach for adhesive products with remarkable confidence. From repairing a shattered ceramic mug to securing a loose tile, modern glues seem to possess almost magical bonding properties. Among them, cyanoacrylate—universally known as “super glue”—holds a particular mystique. It bonds skin in seconds, plastics in moments, and creates famously strong, brittle joins. This potency often leads to a curious question, especially when considering applications near heaters, electronics, or engines: Can a glue, particularly super glue, truly be fireproof?

The short answer is nuanced: No, standard cyanoacrylate “super glue” is not fireproof, and true “fireproof” adhesives are a specialized class of materials. However, understanding why this is the case opens a fascinating window into polymer chemistry, thermal decomposition, and the rigorous science of creating materials that can withstand extreme conditions. This article will dissect the science behind super glue, explore what “fireproof glue” means in materials science, and examine the advanced adhesives that genuinely earn that title.

Deconstructing the Magic: The Chemistry of Cyanoacrylate

To understand its limits, we must first understand how super glue works. The active ingredient in super glue is an alkyl cyanoacrylate monomer (commonly ethyl-2-cyanoacrylate or methoxyethyl cyanoacrylate). In its liquid state, these monomers are stable because of inhibitors that prevent premature polymerization.

The magic—and the weakness—lies in its catalyst: water. The instant the fireproof glue contacts a surface, even the trace amounts of moisture present in the air or on virtually any material (including your fingers) act as a catalyst. This initiates an anionic polymerization reaction. The monomers rapidly link together into long, rigid chains of polycyanoacrylate, forming a solid plastic network that locks the surfaces together.

Key Characteristics of this Reaction:

- Speed: The reaction is extraordinarily fast, leading to quick setting times.

- Exothermic: It releases a small amount of heat.

- Resultant Polymer: The resulting plastic is strong in tensile strength (resists pulling apart) but brittle, with poor resistance to shear (sideways force) and impact.

- Thermal Profile: This is the critical point. Polycyanoacrylate has a relatively low glass transition temperature (Tg)—the temperature at which the polymer changes from a hard, glassy state to a softer, rubbery one. For standard ethyl cyanoacrylate, this is around 80-100°C (176-212°F). Above this temperature, the bond begins to soften and lose its integrity.

The Flammability Reality: Thermal Decomposition

When we ask if something is “fireproof,” we are really asking two questions: 1) Will it catch fire easily? and 2) Will it retain its structural integrity when exposed to fire or high heat?

For standard super glue, the answer to both is unfavorable.

- Ignition: While not highly flammable like gasoline, cyanoacrylate in its liquid monomer form can combust. The vapors can be irritating and, in confined spaces with high concentration, potentially ignitable.

- Thermal Decomposition: More importantly, the solid polymer bond thermally decomposes at relatively modest temperatures. When heated above approximately 165°C (330°F), the polycyanoacrylate chains begin to break down (unzip) in a process that can revert them back to their monomer form—a process known as depolymerization. This releases flammable cyanoacrylate vapors and other toxic fumes, including cyanide compounds and carbon monoxide.

In a fire scenario, a super glue bond doesn’t just fail; it actively contributes to the fuel load and releases toxic smoke. It exhibits what material scientists call a “lack of thermal oxidative stability.” Therefore, labeling it as “fireproof” would be dangerously inaccurate.

Defining “Fireproof” in Adhesives

In materials science, terms like “fireproof,” “fire-resistant,” and “non-flammable” have specific meanings governed by international standards (e.g., UL 94, ASTM E84). “Fireproof” is often considered an absolute term rarely applied to organic materials; “highly fire-resistant” or “intumescent” are more accurate.

A true fire-resistant adhesive is engineered to do one or more of the following:

- Withstand High Temperature: Maintain bond strength and structural integrity at continuous high temperatures (e.g., 200°C to over 1000°C).

- Charing and Insulation: Form a stable, insulating char layer when exposed to flame, protecting the substrate and the underlying adhesive.

- Intumescence: Swell and expand when heated, forming a thick, insulating foam that protects the bonded joint and seals gaps.

- Low Flammability and Smoke Production: Have a high Limiting Oxygen Index (LOI), meaning they require a high concentration of ambient oxygen to burn, and produce minimal toxic smoke.

The Real Fire-Resistant Champions: Adhesives That Withstand the Heat

When a task demands thermal resilience, engineers turn to entirely different chemical families. These are not your typical hardware store glues.

- a) Epoxy Resins (Modified):

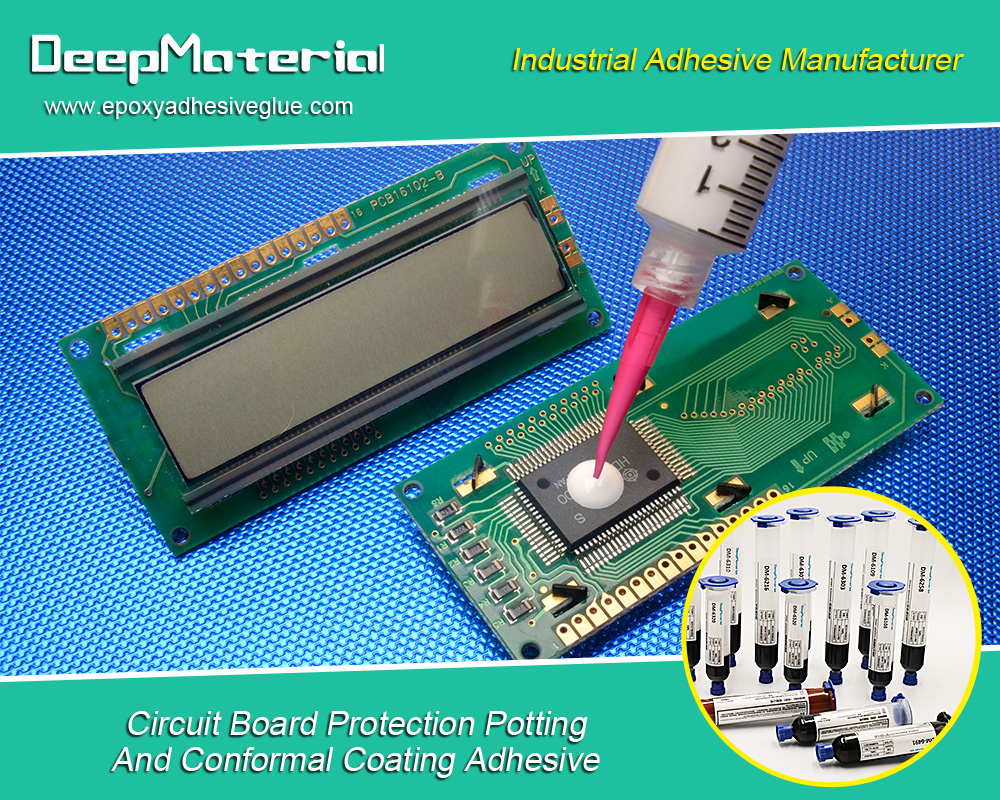

Standard epoxies begin to soften around 60-120°C. However, high-temperature epoxy formulations, often using tetraglycidyl methylene dianiline (TGMDA) and cured with aromatic amines like diamino diphenyl sulfone (DDS), can have continuous service temperatures up to 150-200°C. For even higher performance, phenolic or bismaleimide (BMI) resins are used, offering stability up to 250-300°C and exceptional flame, smoke, and toxicity (FST) ratings. These are staples in aerospace composites.

- b) Silicone Adhesives:

Silicones, with their inorganic silicon-oxygen backbone, excel where flexibility and heat resistance are needed. High-temperature silicone sealants/adhesives can operate continuously from -60°C to over 250°C, with some specialty formulations reaching 300°C. They form rubbery bonds that accommodate thermal expansion and are inherently flame retardant, forming a non-combustible silica ash (char) when exposed to extreme heat.

- c) Inorganic Adhesives:

These are the true heavyweights. They contain no organic (carbon-based) compounds to burn.

- Sodium Silicate (Water Glass): Used for bonding ceramics and in high-temperature gaskets. It sets into a hard, glassy, and completely non-flammable bond.

- Phosphate Cements: Ceramic-based adhesives that can withstand temperatures exceeding 1000°C. They are used in furnace repairs, aerospace thermal protection systems, and bonding refractory metals.

- Geopolymer Adhesives: A newer class, forming a ceramic-like structure from aluminosilicate materials, offering exceptional fire and chemical resistance.

- d) Intumescent Adhesives:

Common in construction for fire-stopping, these adhesives are designed to expand dramatically when heated, forming a carbonaceous char foam that insulates steel beams, seals penetrations in firewalls, and prevents the spread of flame and smoke.

The Glue in Your Hand: Fire-Related Claims and Enhancements

You may encounter super glue products labeled as “high temperature” or “heat resistant.” These are typically modified cyanoacrylates. Enhancements can include:

- Toughening Agents: Rubbery additives to improve impact and peel resistance, which can marginally improve thermal performance by absorbing stress.

- Altered Alkyl Chains: Using longer or different alkyl chains (like butyl or methoxyethyl) can raise the Tg slightly, perhaps to 120-150°C range—useful for a car’s interior but not for an exhaust manifold.

- Additives: Incorporating fine, thermally stable fillers like silica or metal powders can help dissipate heat and slow decomposition.

Crucially, even these “enhanced” cyanoacrylates are not fireproof. They are simply formulated to survive in environments where standard super glue would fail, such as near engine blocks or in sun-exposed automotive applications. Their decomposition temperature might be raised by 20-40°C, but the fundamental chemistry remains vulnerable to direct flame and sustained high heat.

The Verdict: A Matter of Chemistry and Application

So, can a glue be fireproof? The conclusion is clear:

- Standard Cyanoacrylate (Super Glue): Is flammable, thermally decomposes at moderate temperatures, and is not fireproof. It is an excellent adhesive for room-temperature, indoor applications where its fast setting and strong bonds are needed.

- Fire-Resistant Adhesives: Exist, but they are specialized products based on epoxy, silicone, phenolic, or inorganic chemistry. They are engineered for specific, demanding applications and are defined by their ability to withstand extreme heat, form insulating chars, and exhibit low flammability.

The “super” in super glue refers to its speed and bond strength under ordinary conditions, not its thermal stability. Its chemistry, a rapid polymerization triggered by water, is ill-suited for the brutal, energy-intensive environment of a fire.

Conclusion

The question of fireproof glue underscores a fundamental principle in materials engineering: there is no universal “best” material, only the optimal material for a specific set of conditions. The science reveals a spectrum of adhesives, each with a defined operational window.

For bonding a plastic knob to a stereo, super glue is a marvel of modern chemistry. For sealing a fireplace, constructing a jet engine, or fire-protecting a steel column in a skyscraper, the sophisticated science of high-temperature epoxies, intumescent mastics, or inorganic cements takes over. Understanding the dramatic difference between these worlds—the water-catalyzed chains of cyanoacrylate versus the silicon-oxygen matrices of inorganic sealants—is key to using adhesives safely and effectively. The next time you reach for a glue, remember that its true strength lies not in a blanket claim of being “super,” but in the precise alignment of its chemical design with the task at hand.

For more about can a glue really be fireproof? The science behind the super glue, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.